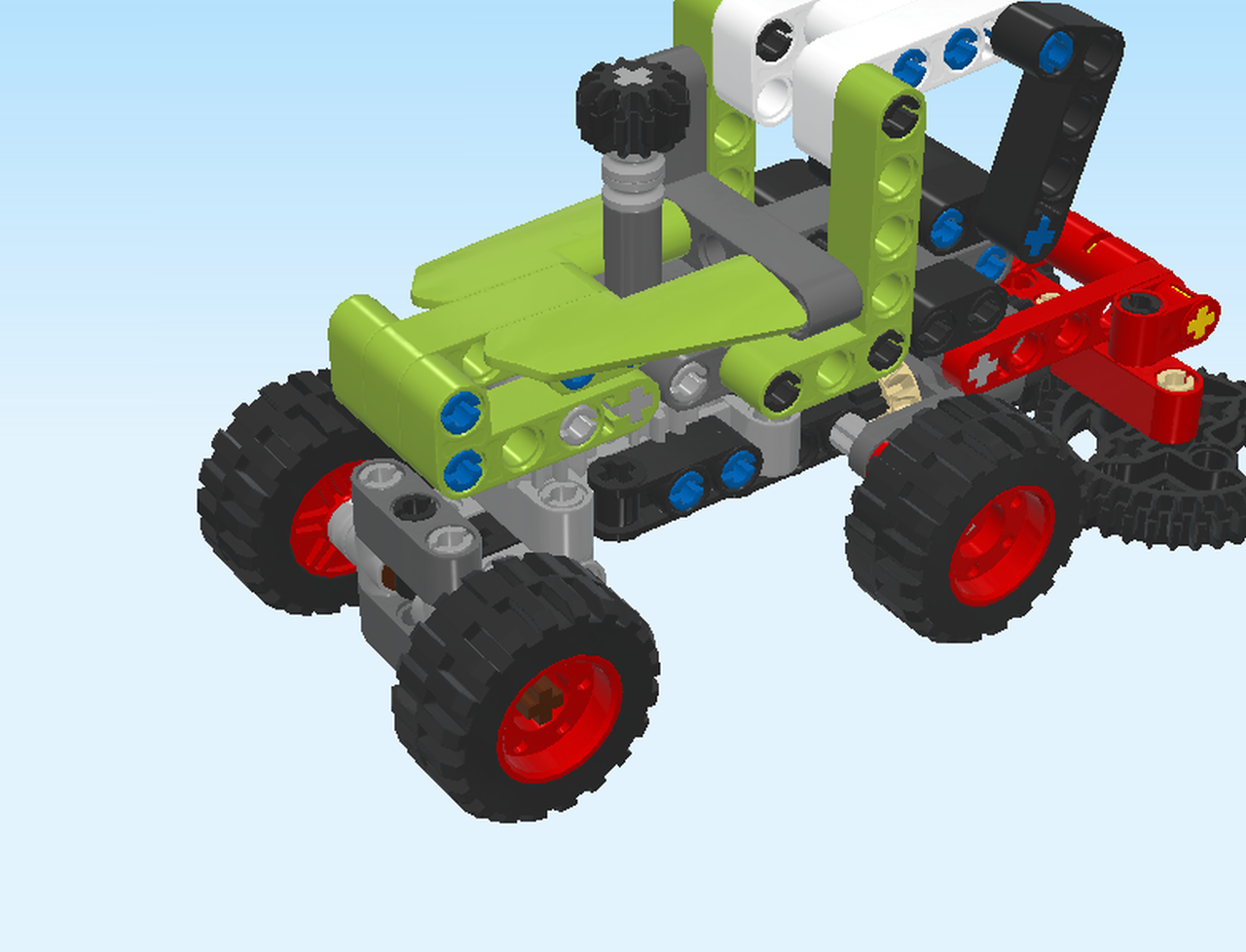

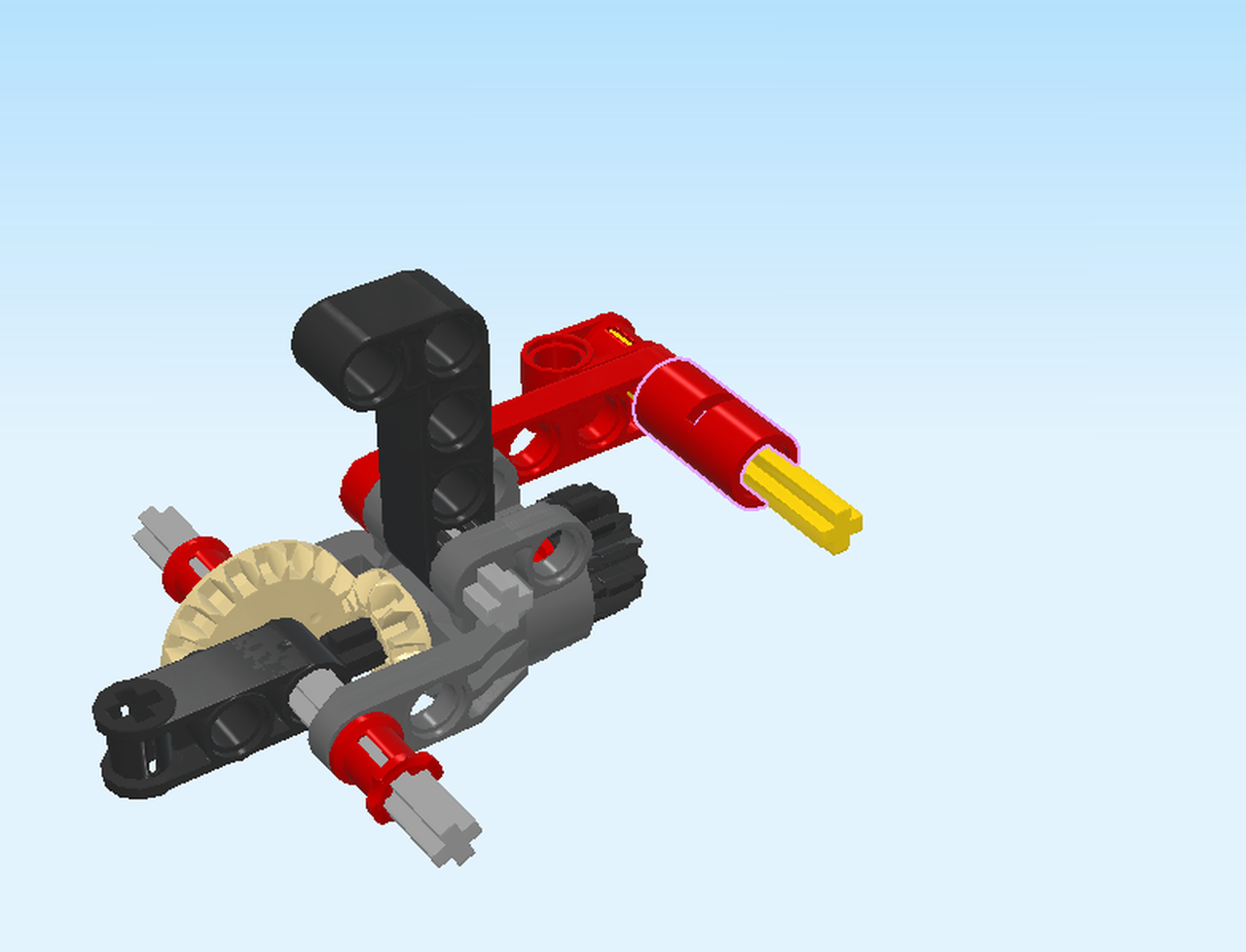

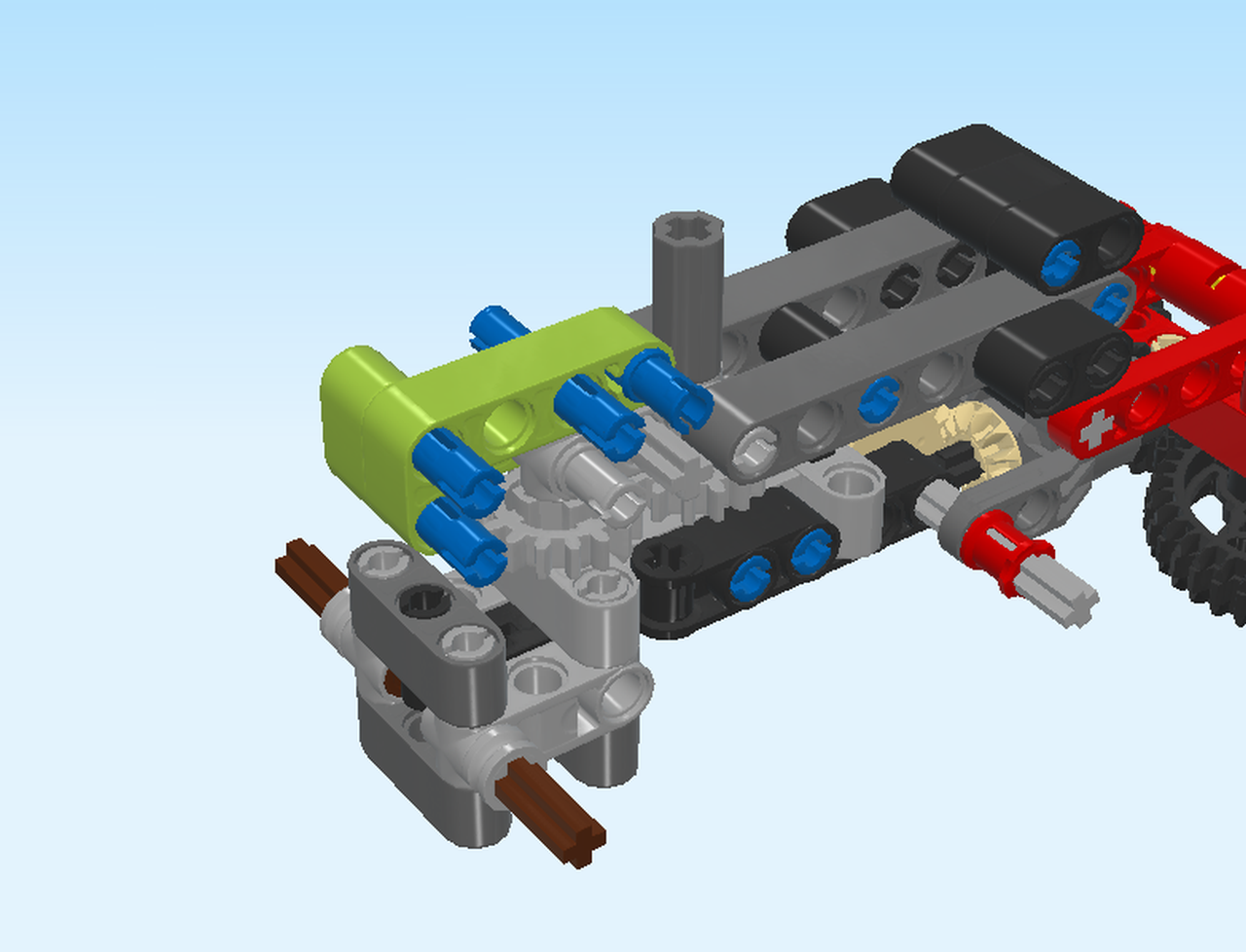

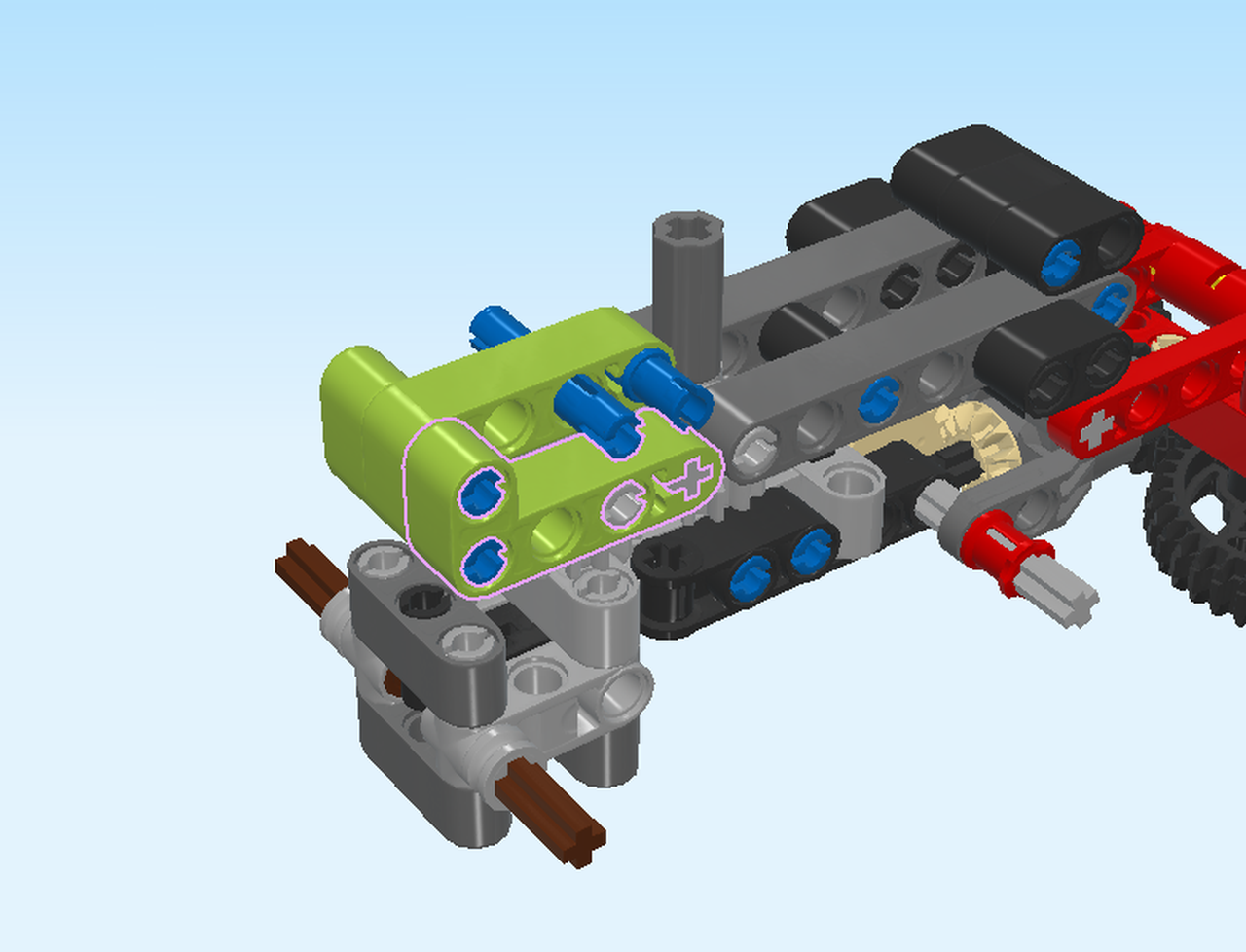

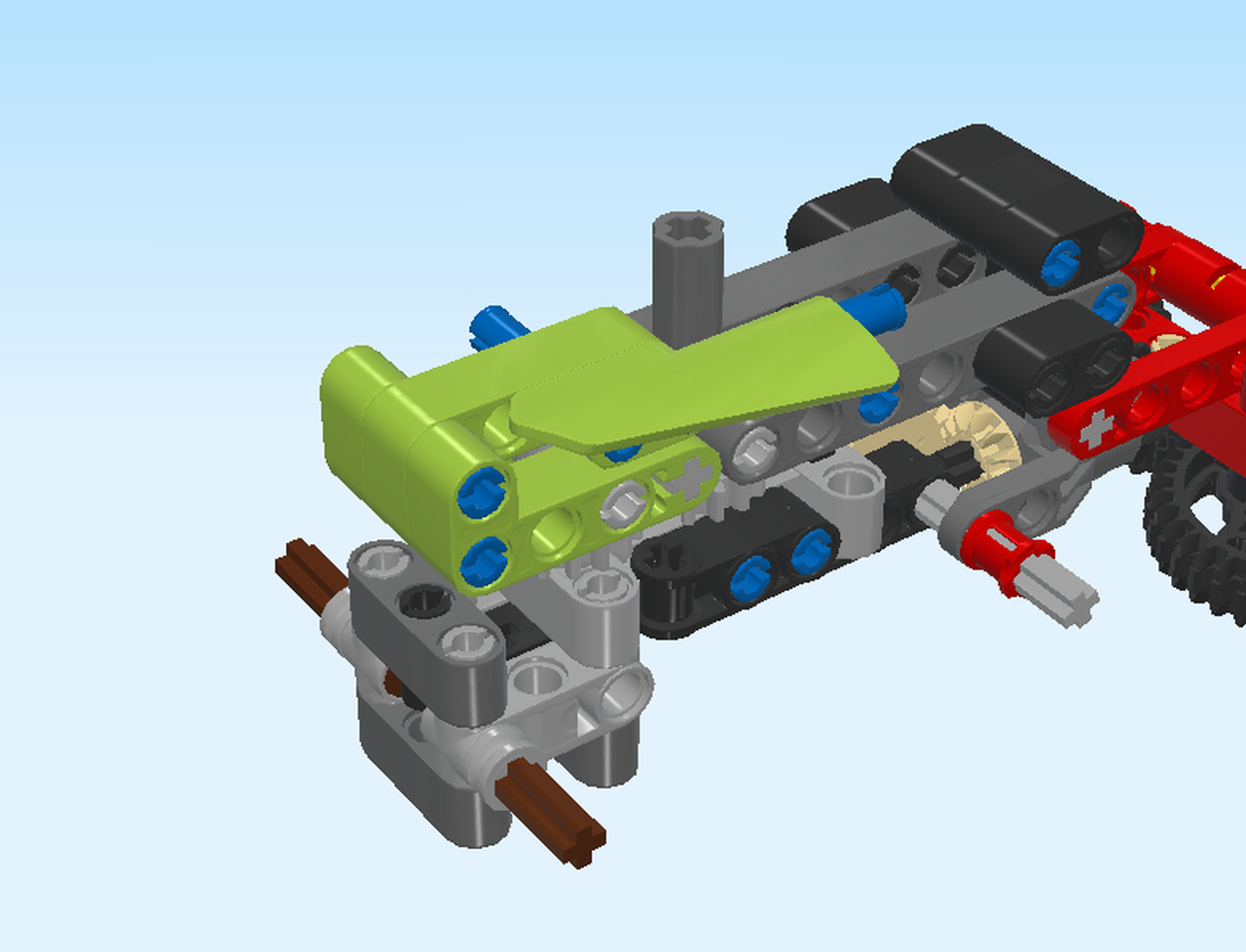

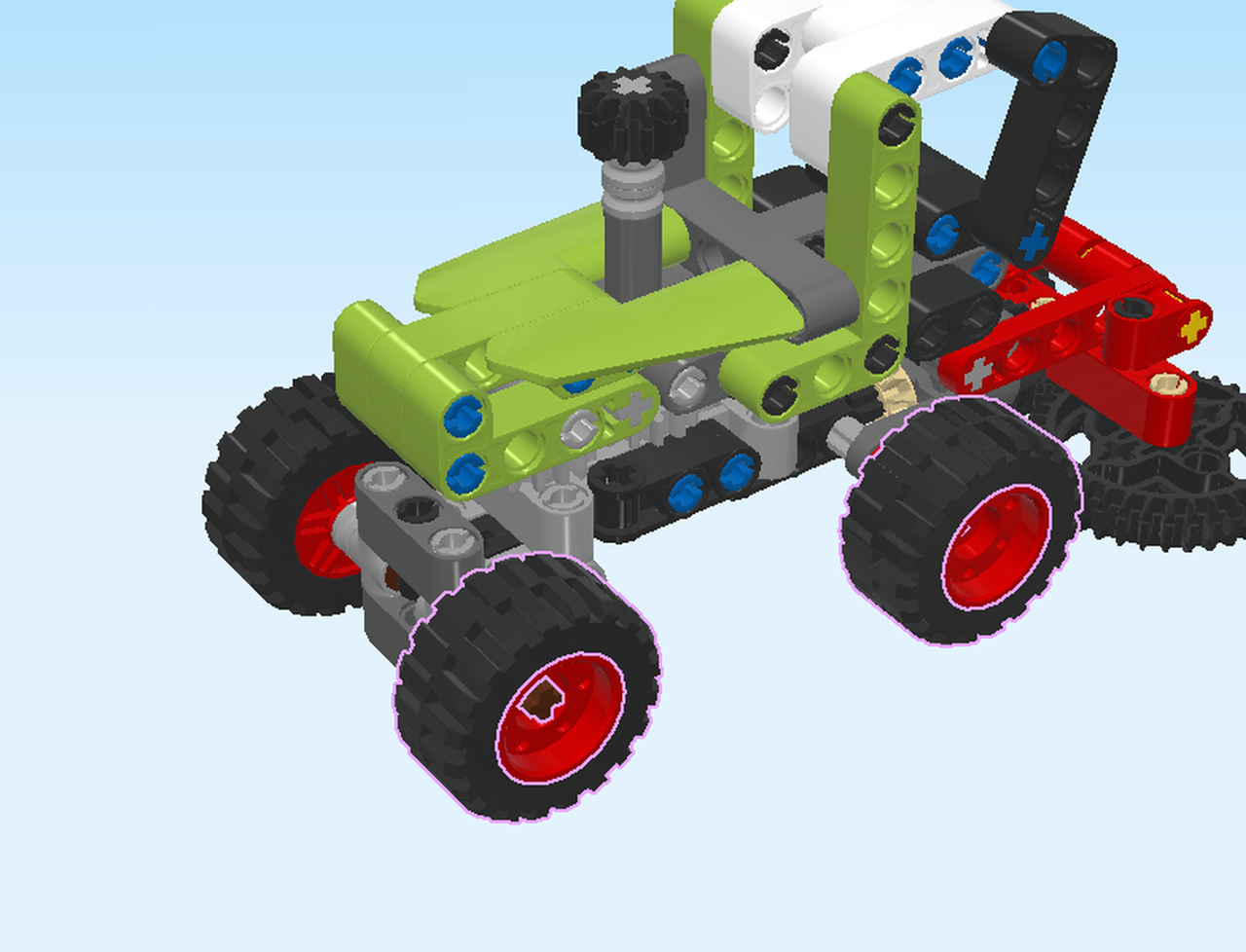

LEGO Audio & Braille Building Instructions for LEGO Technic set "Mini CLAAS XERION harvester".

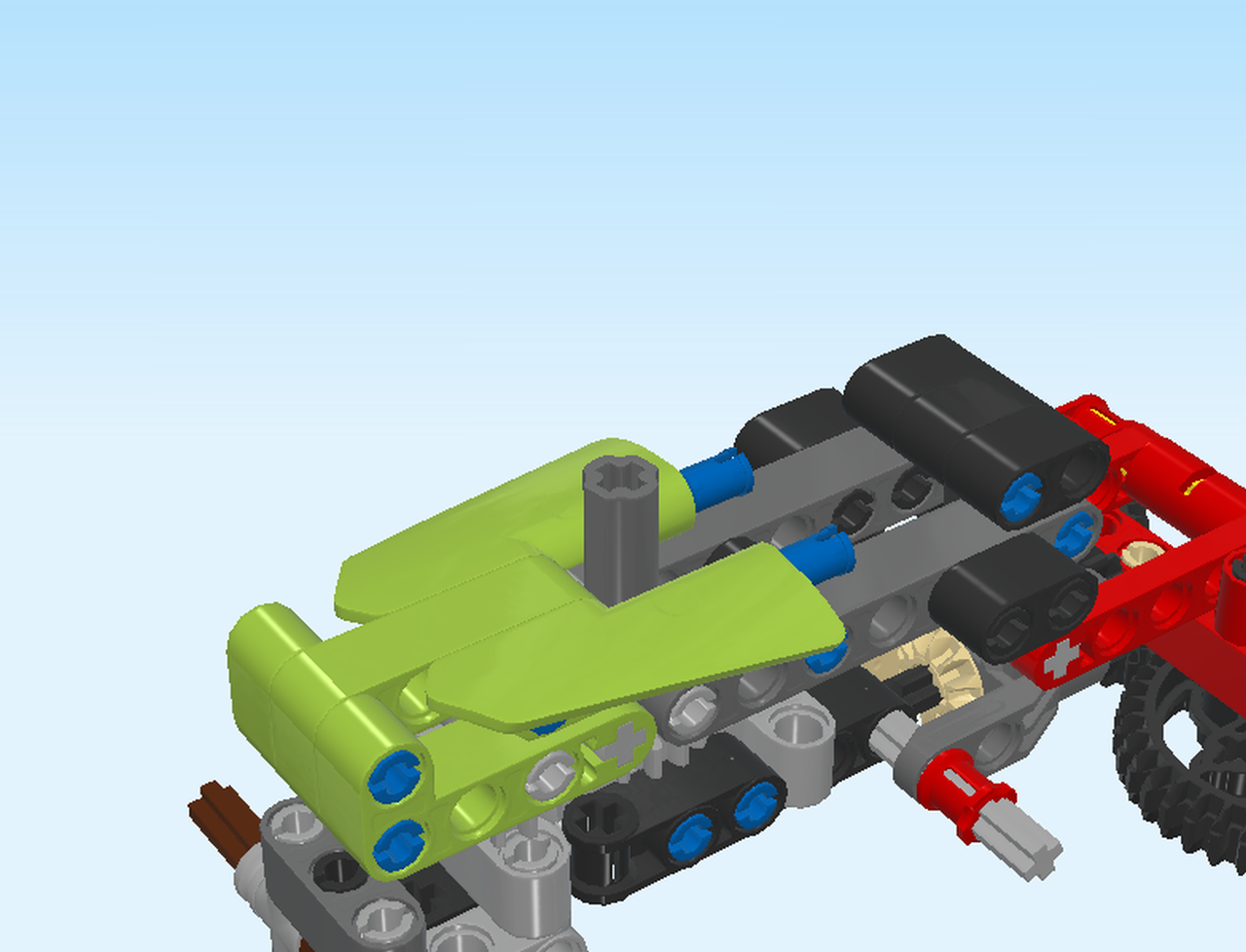

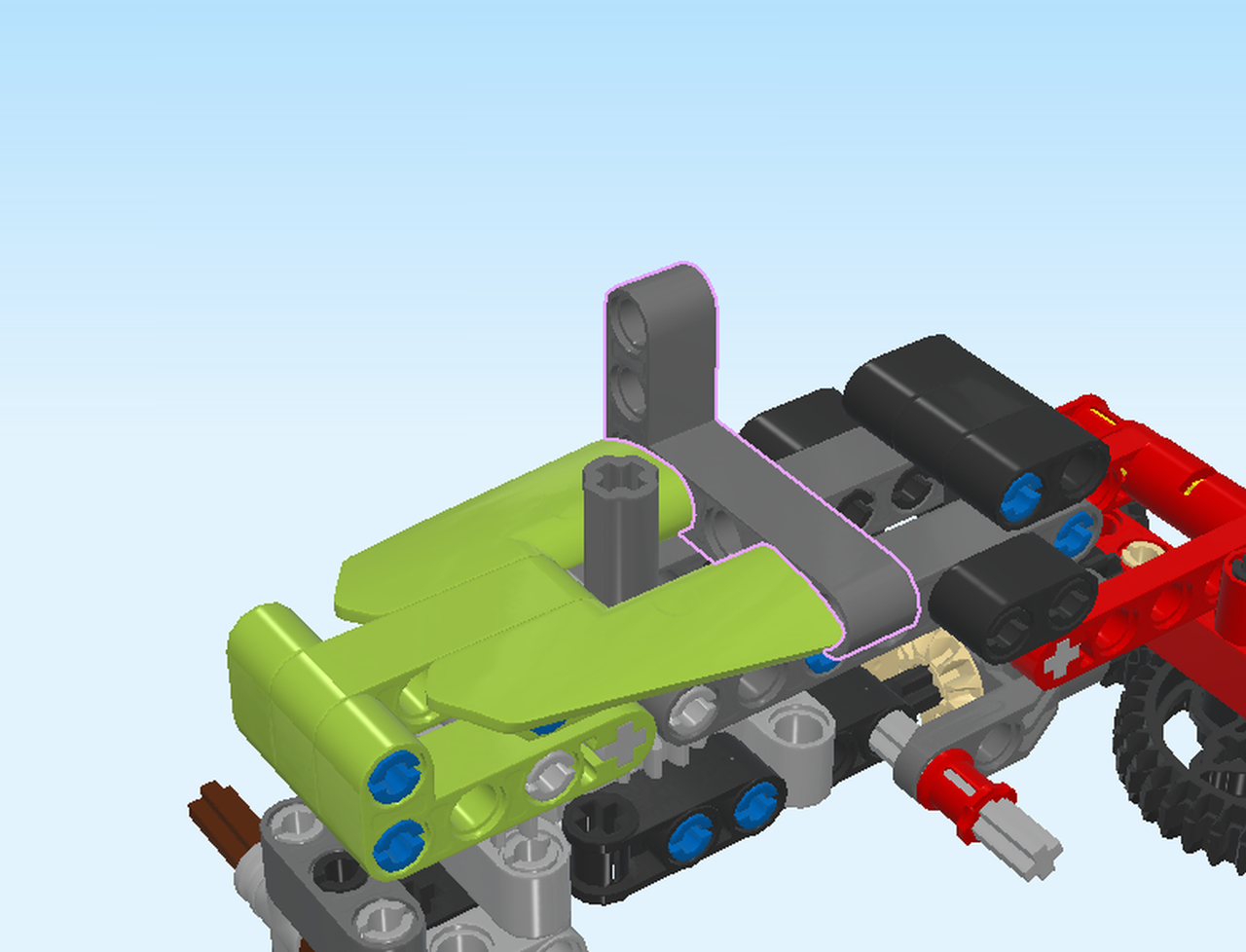

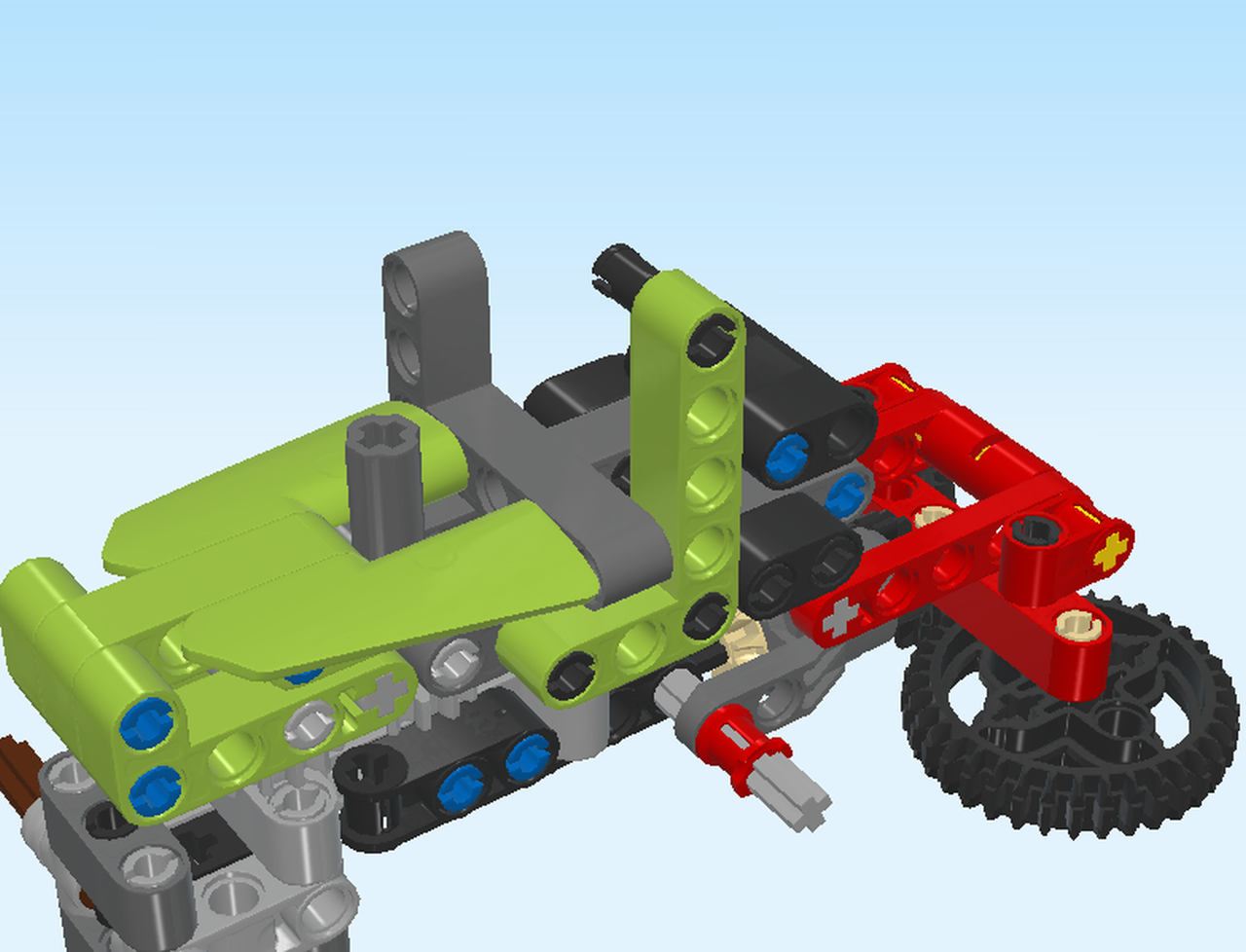

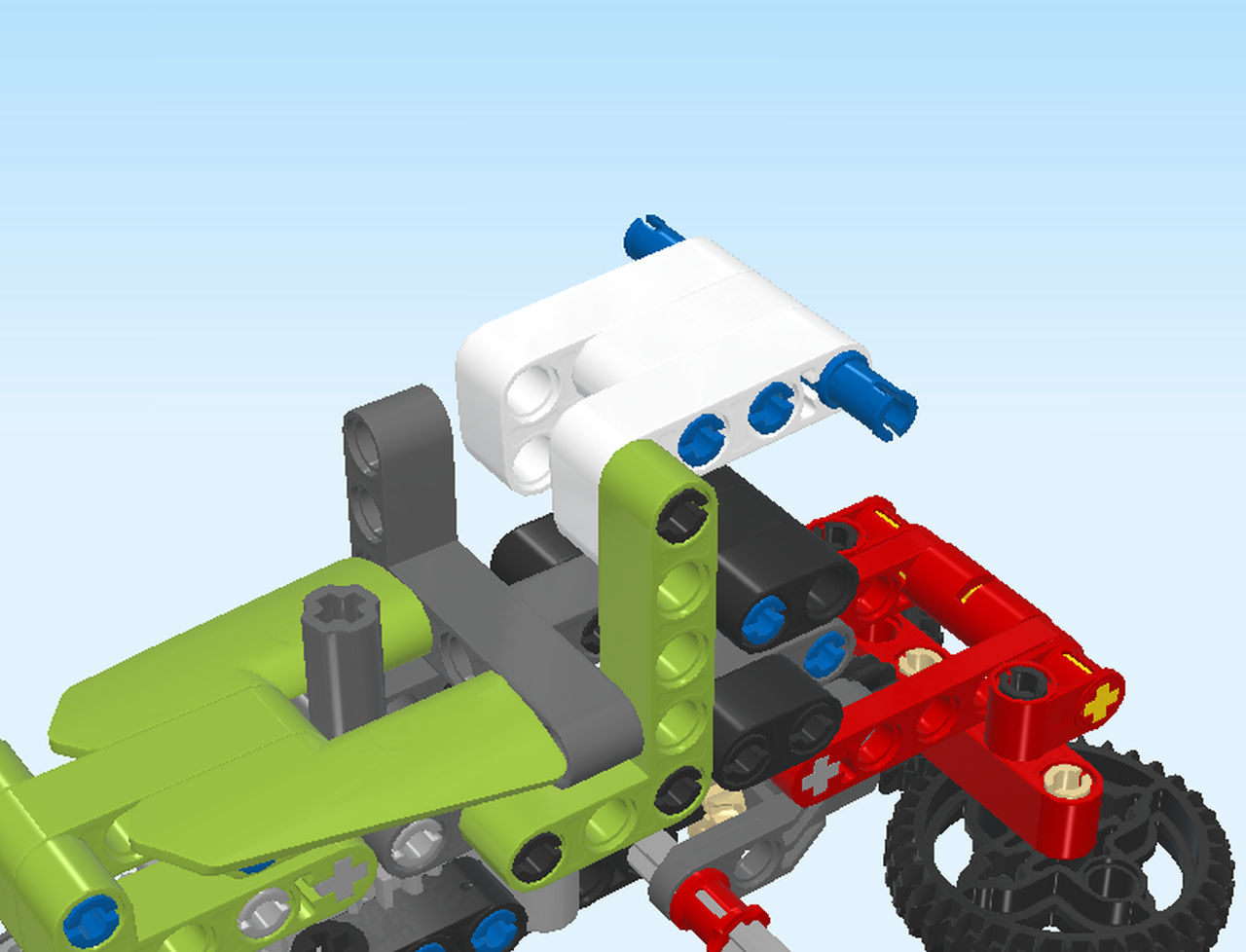

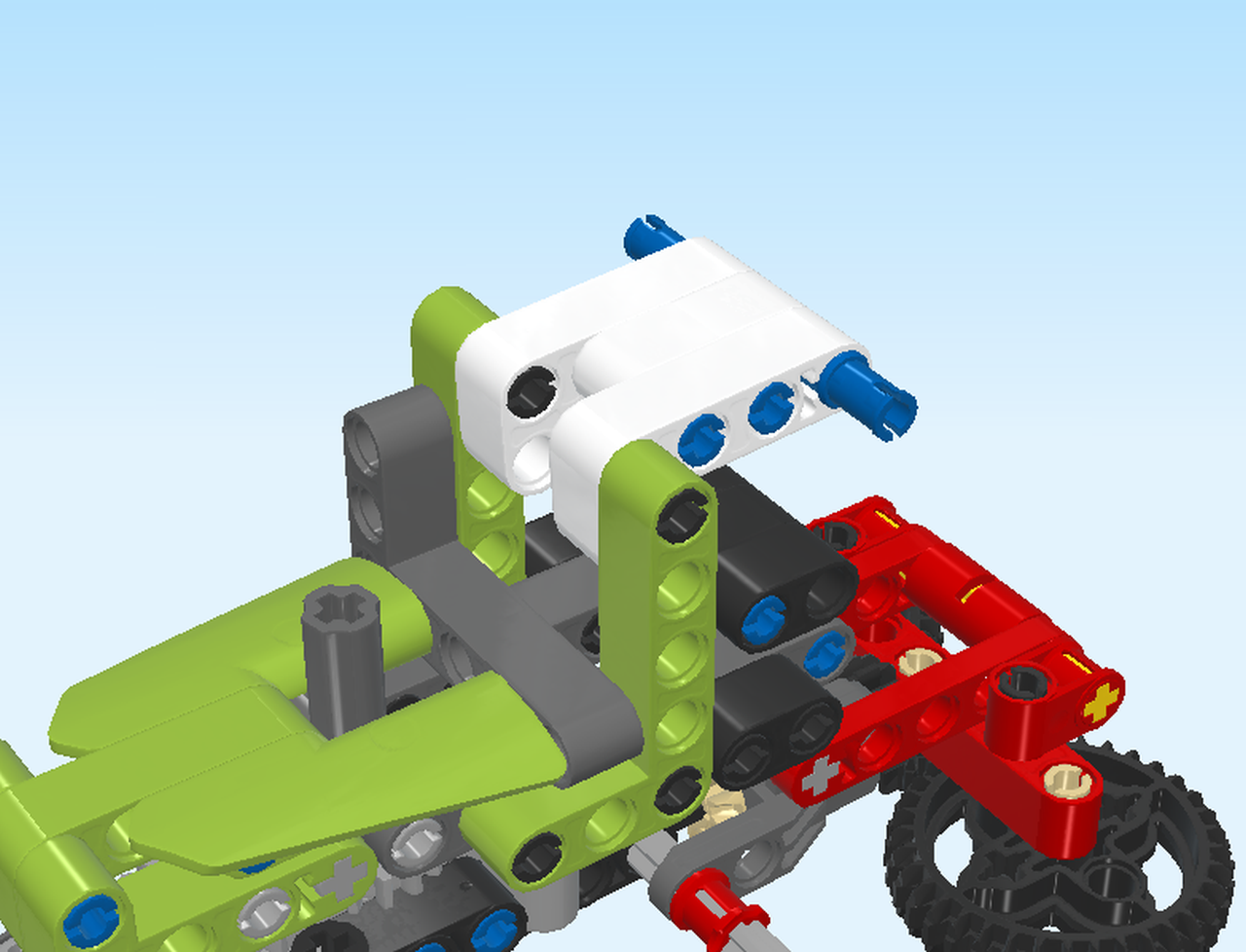

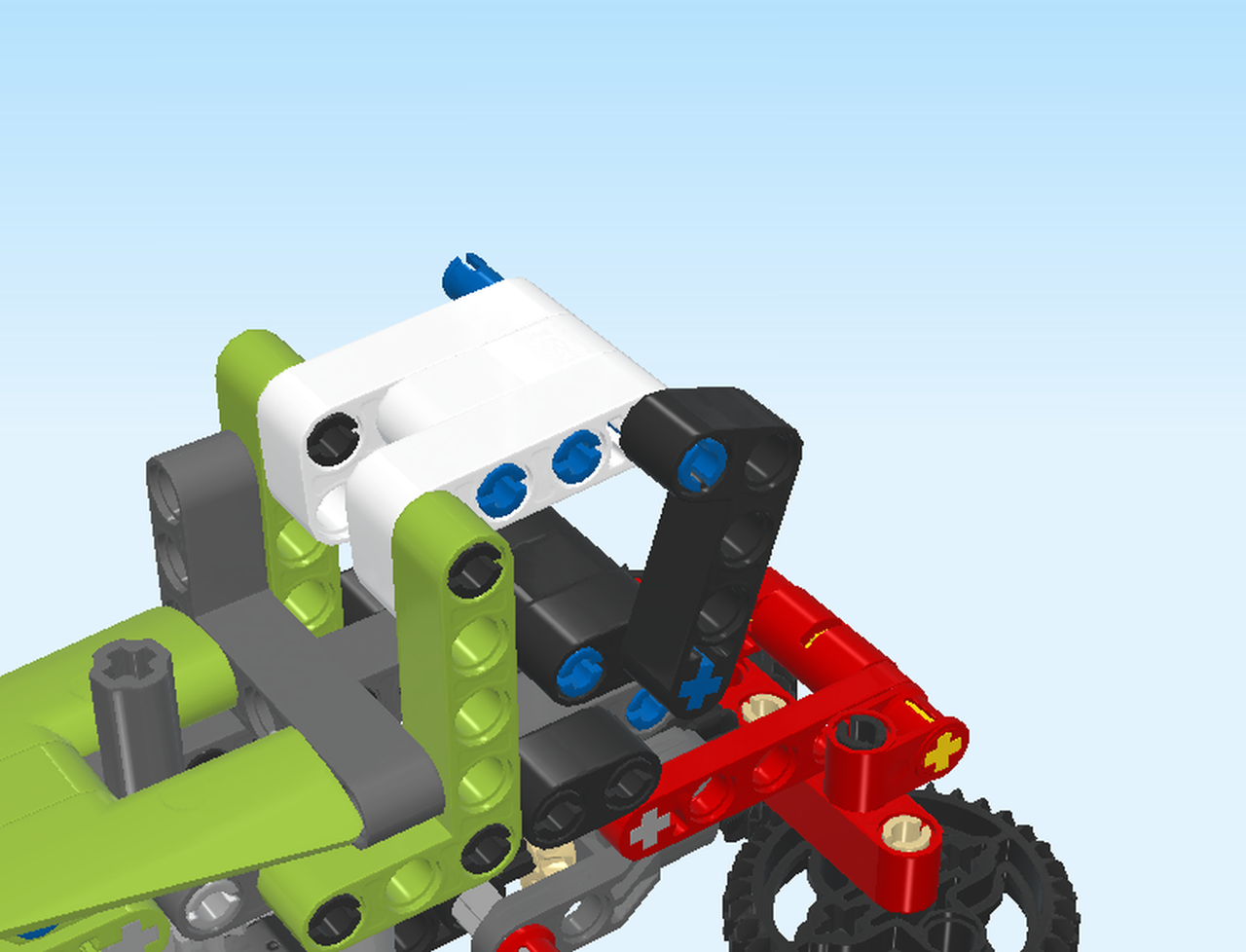

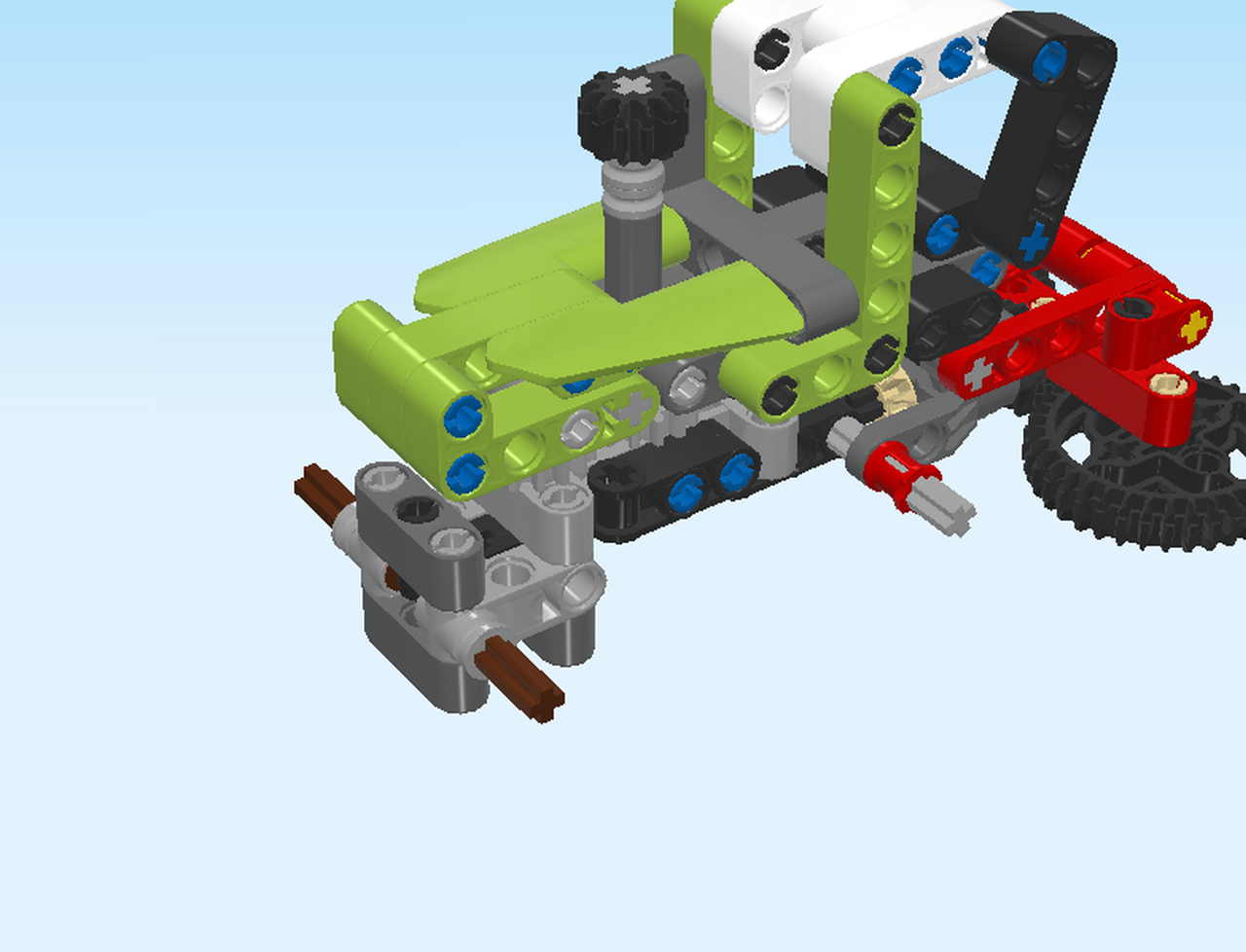

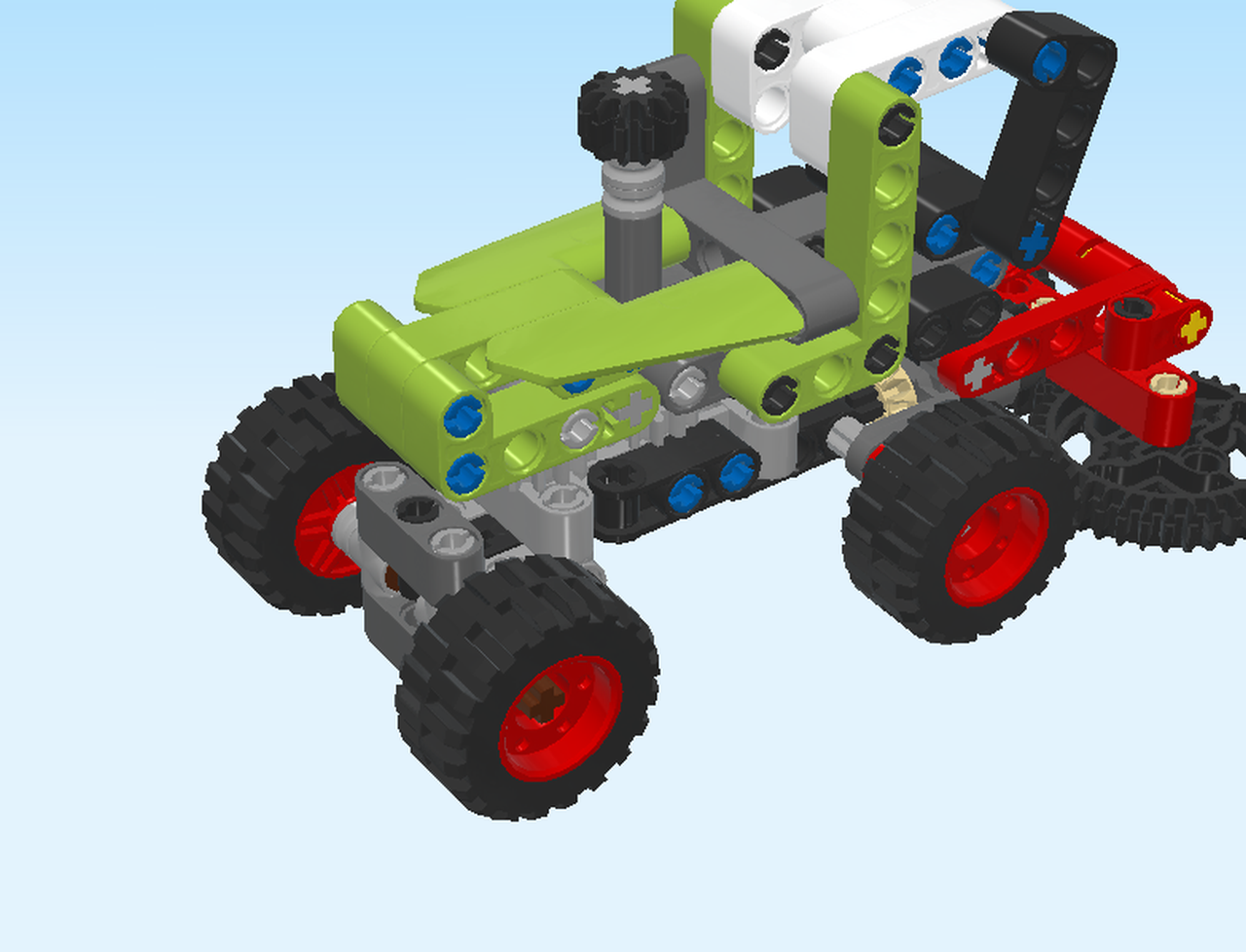

Build your very own LEGO version of a harvester machine from world-famous tractor maker CLAAS! It features the iconic green, red and gray color scheme just like the real CLAAS XERION machines.

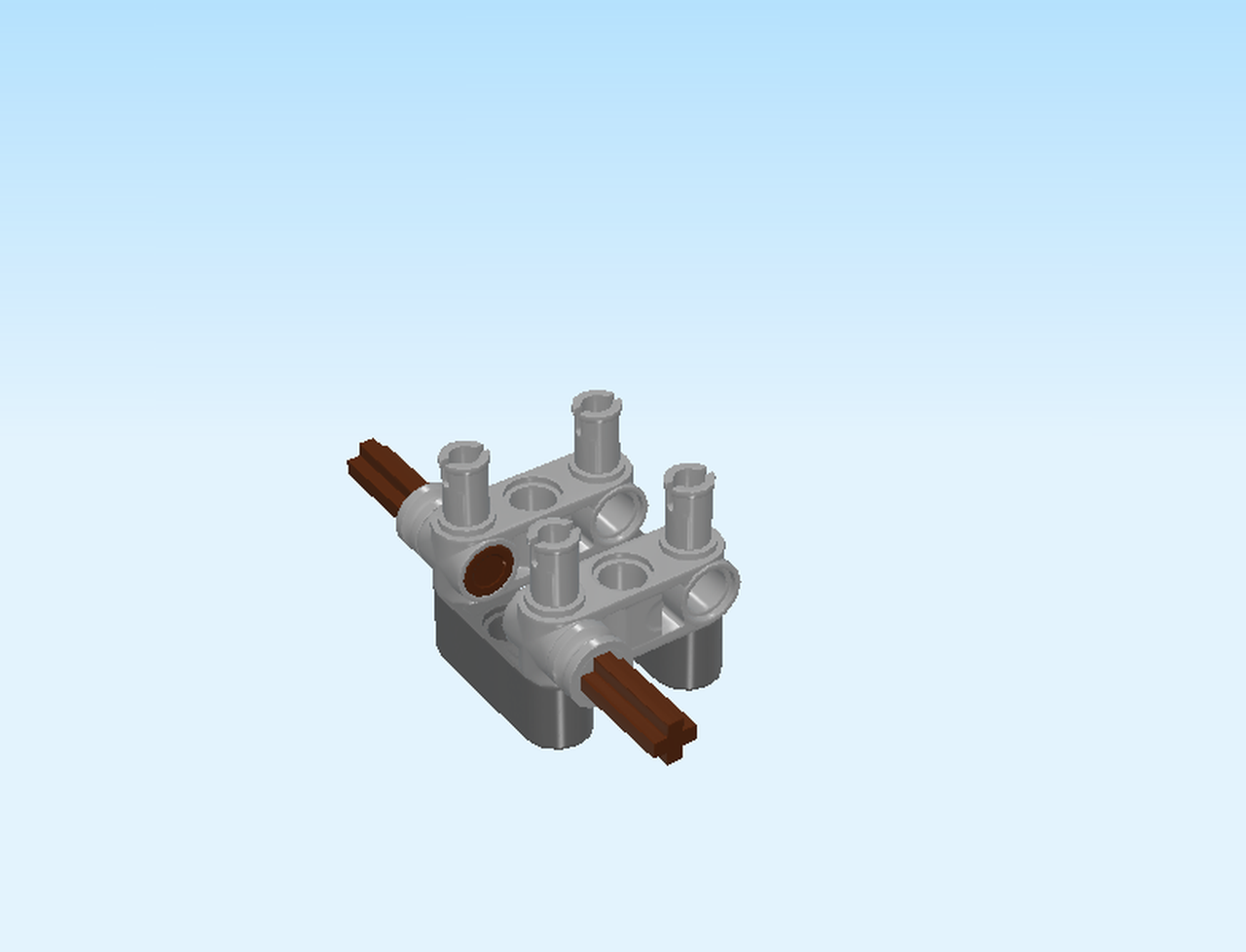

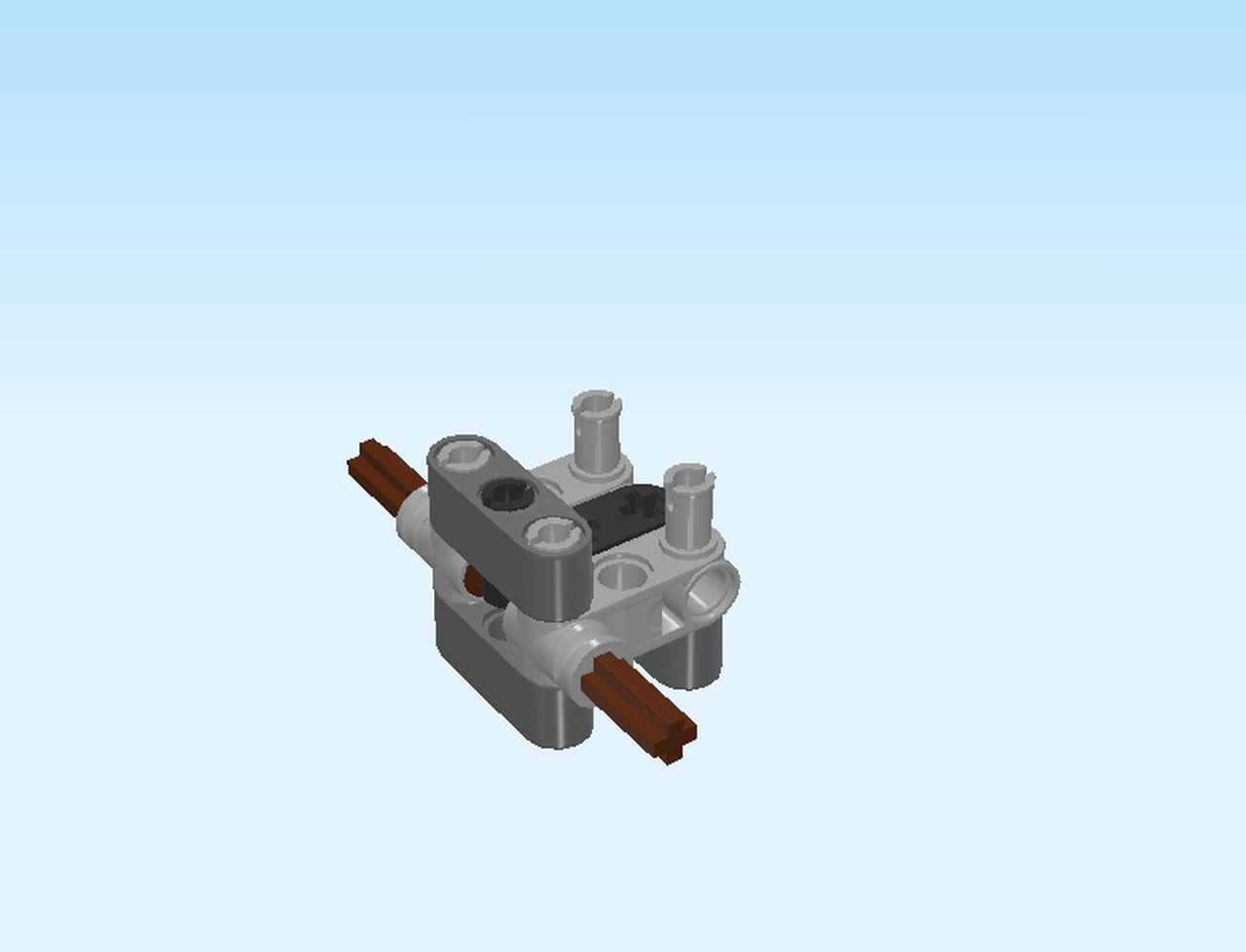

It is harvest time and your wheat crops are ready to be cut and brought home! The CLAAS XERION harvester with its flexible steering and rotary cutters at the back is the perfect machine for this job. Insiders' tip: this LEGO Technic set is a neat 2-in-1 package: alternatively, you can also build the CLAAS XERION tractor with it!

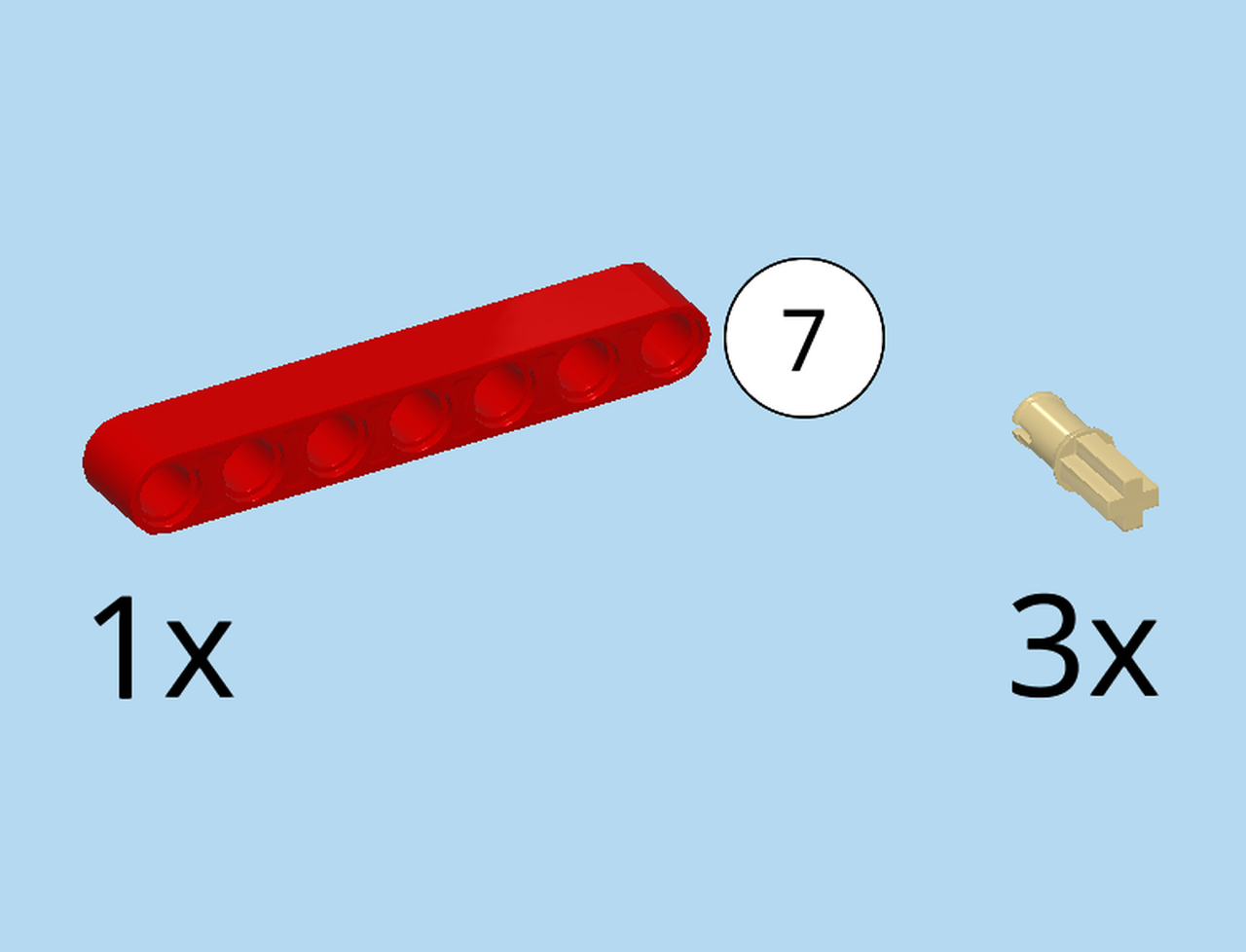

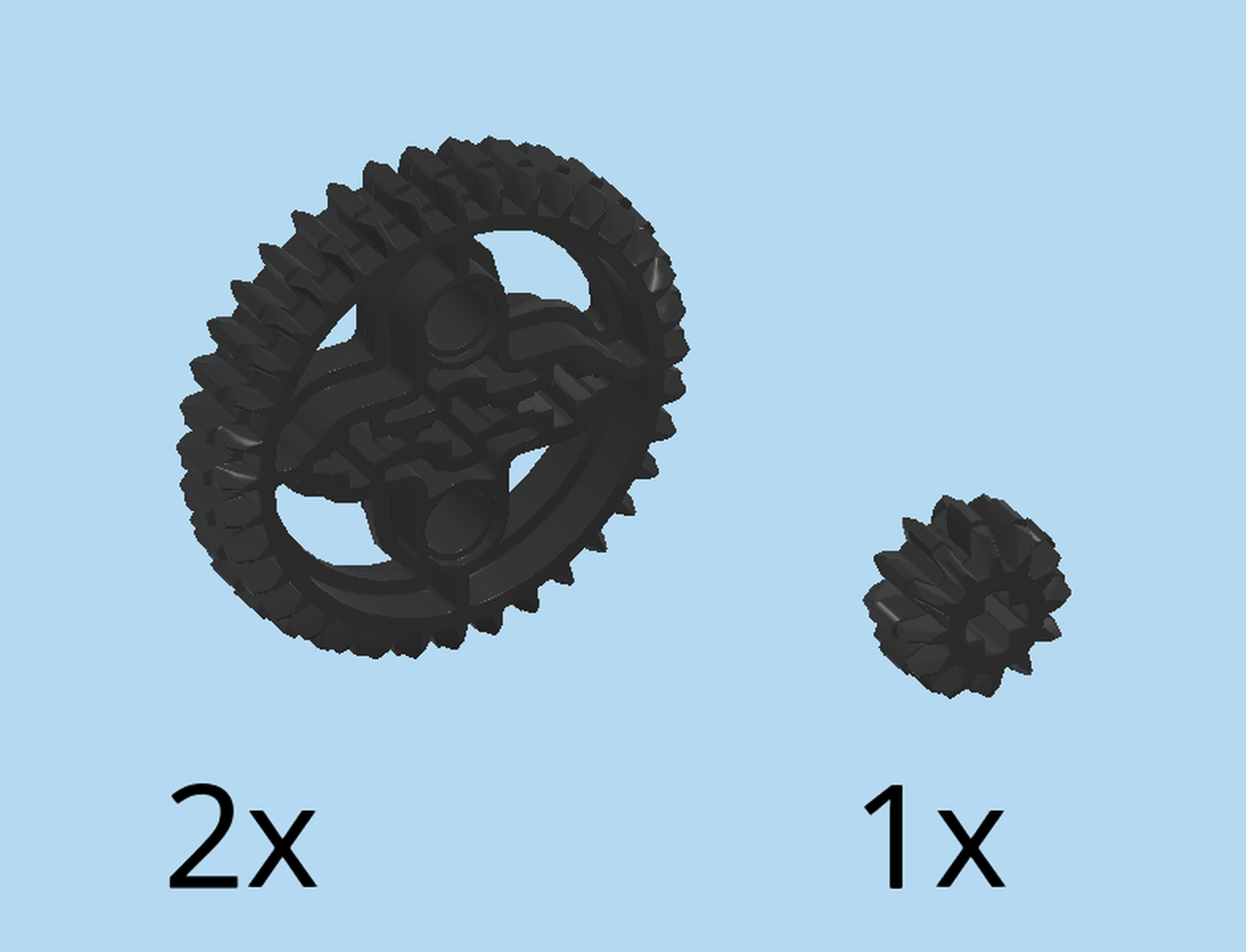

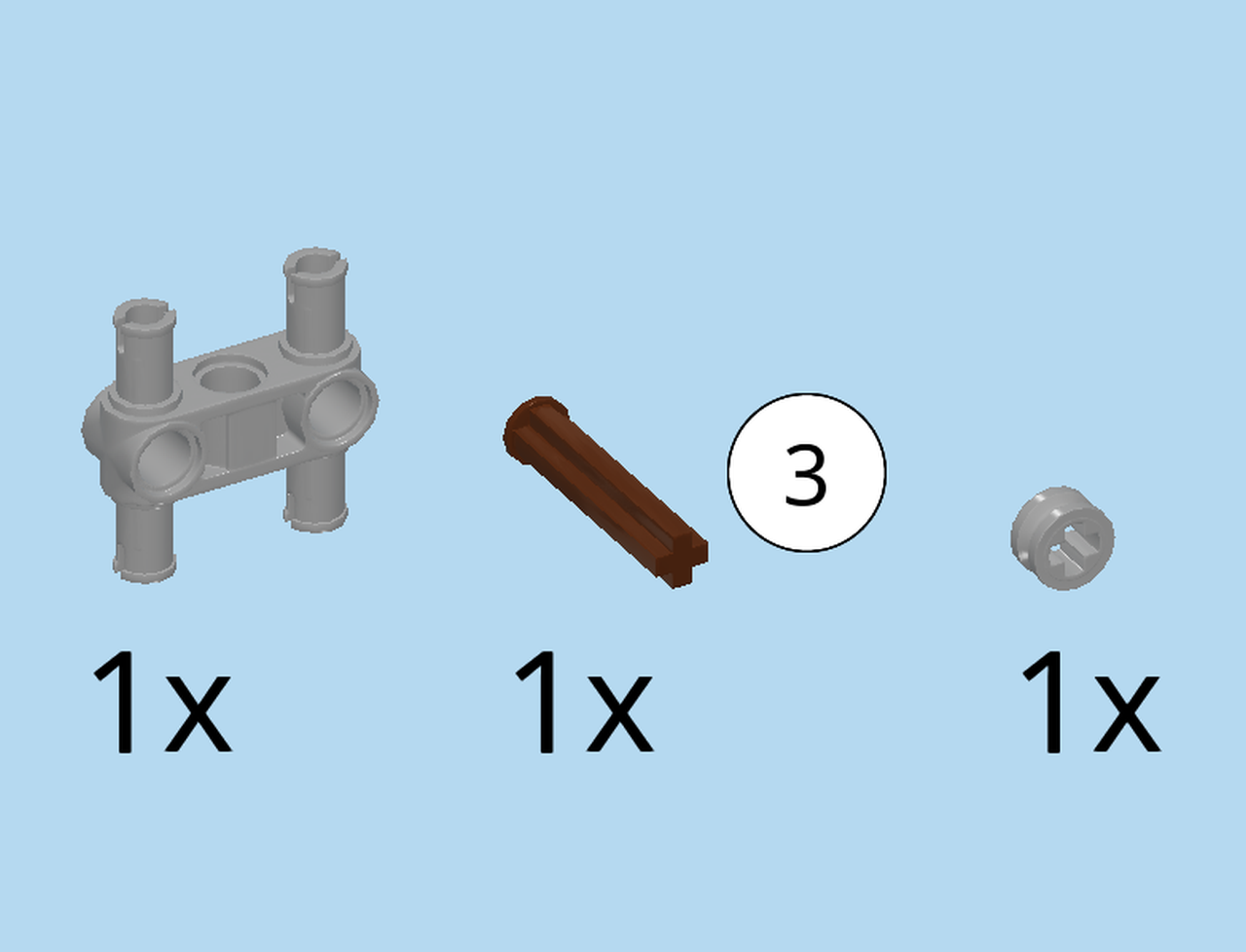

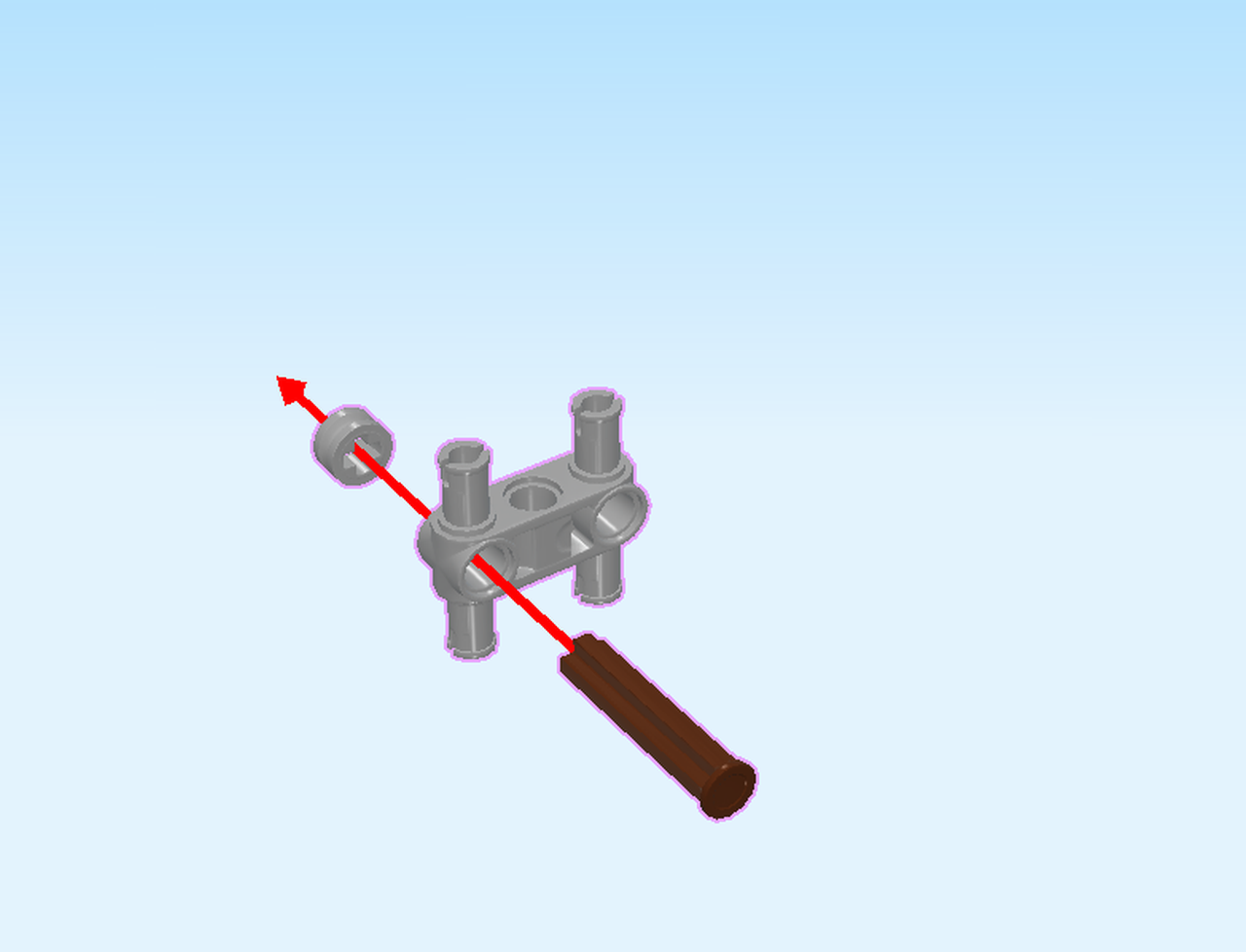

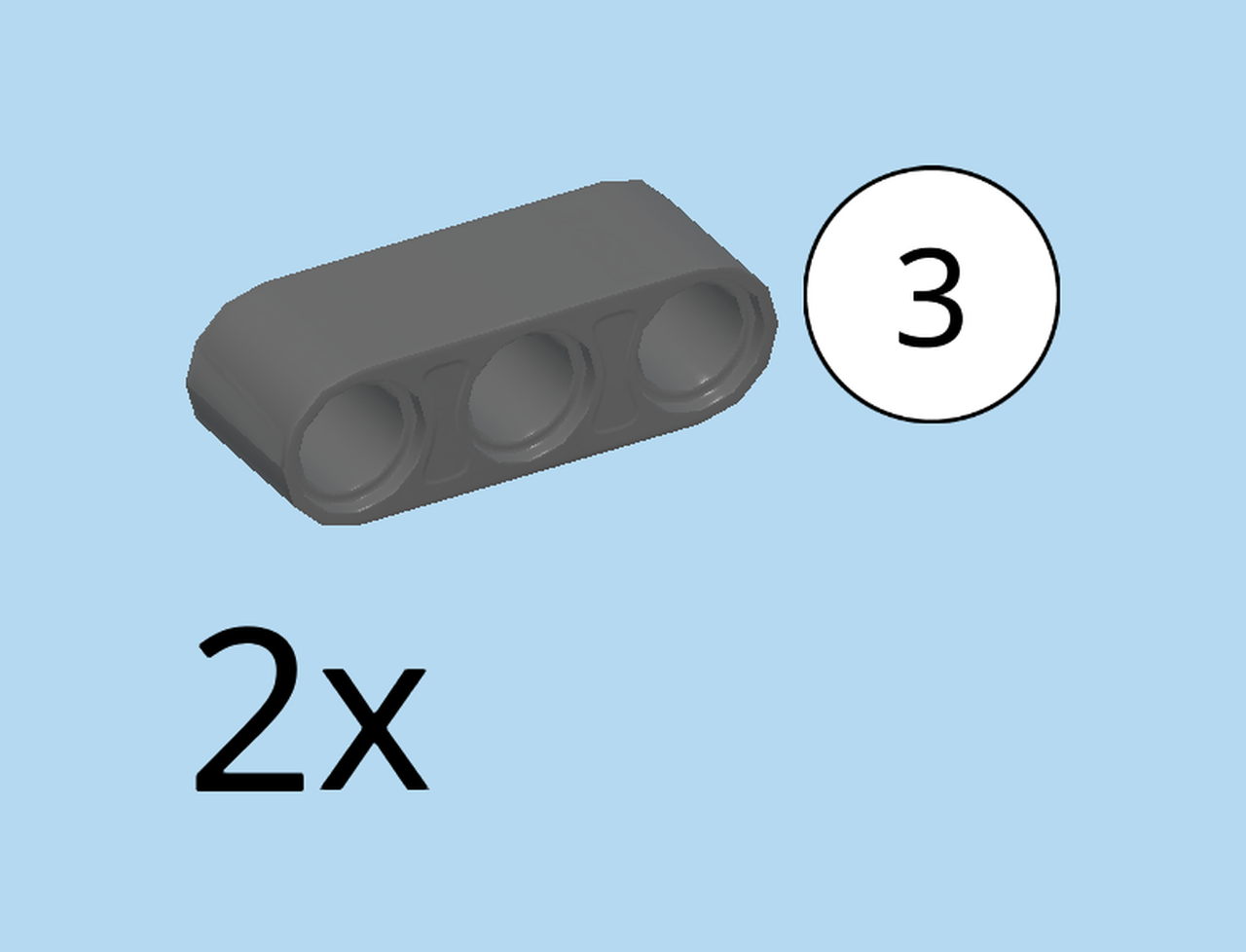

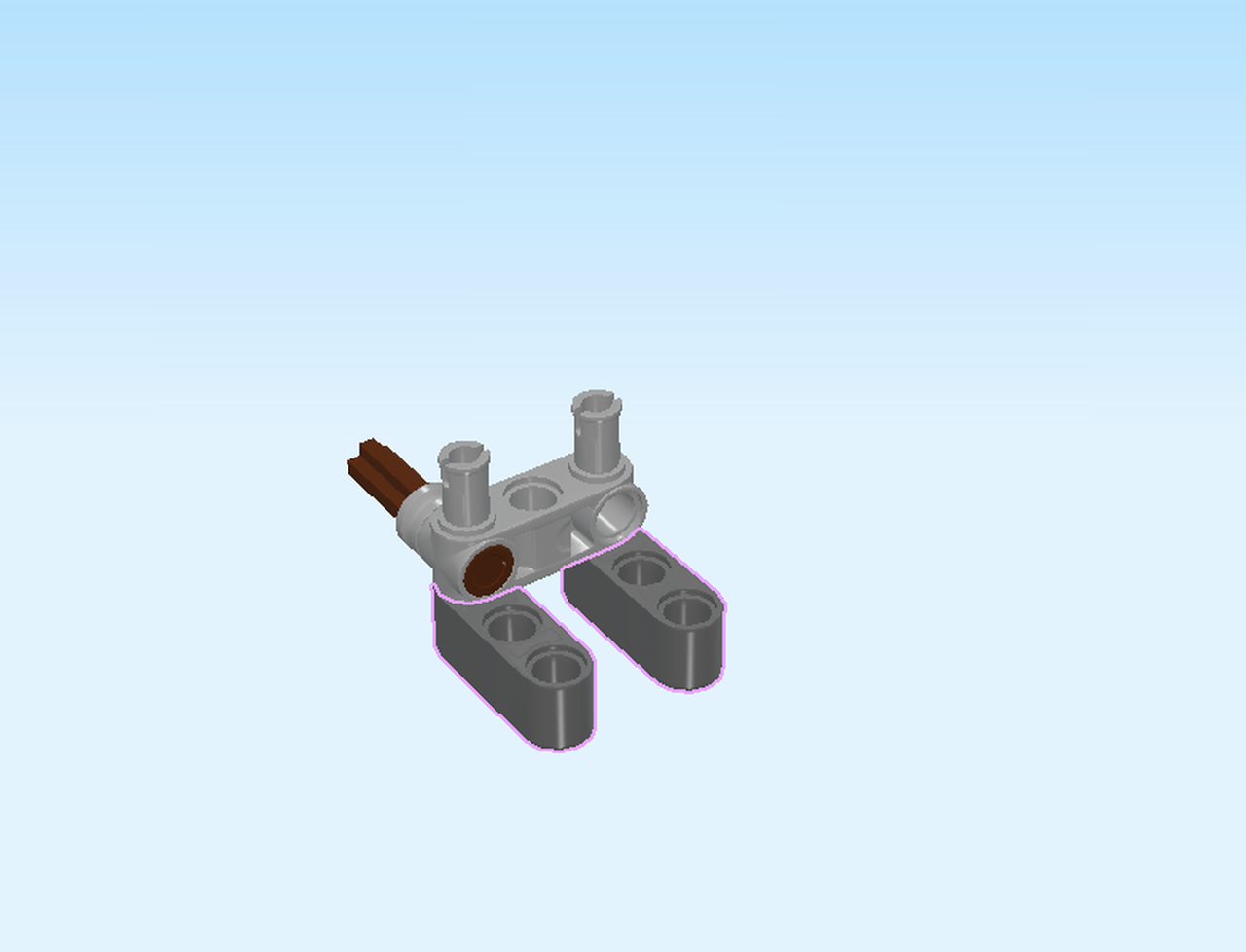

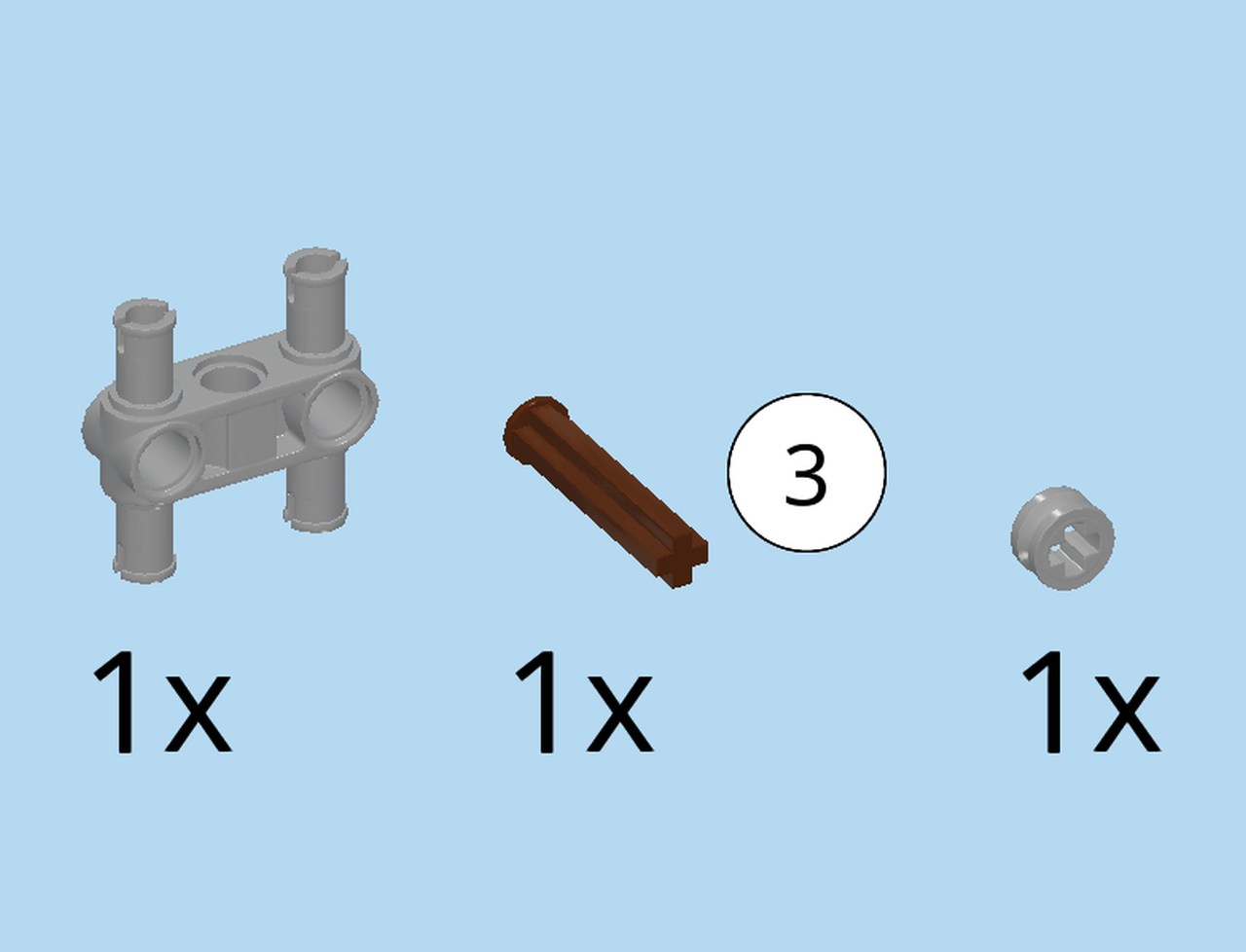

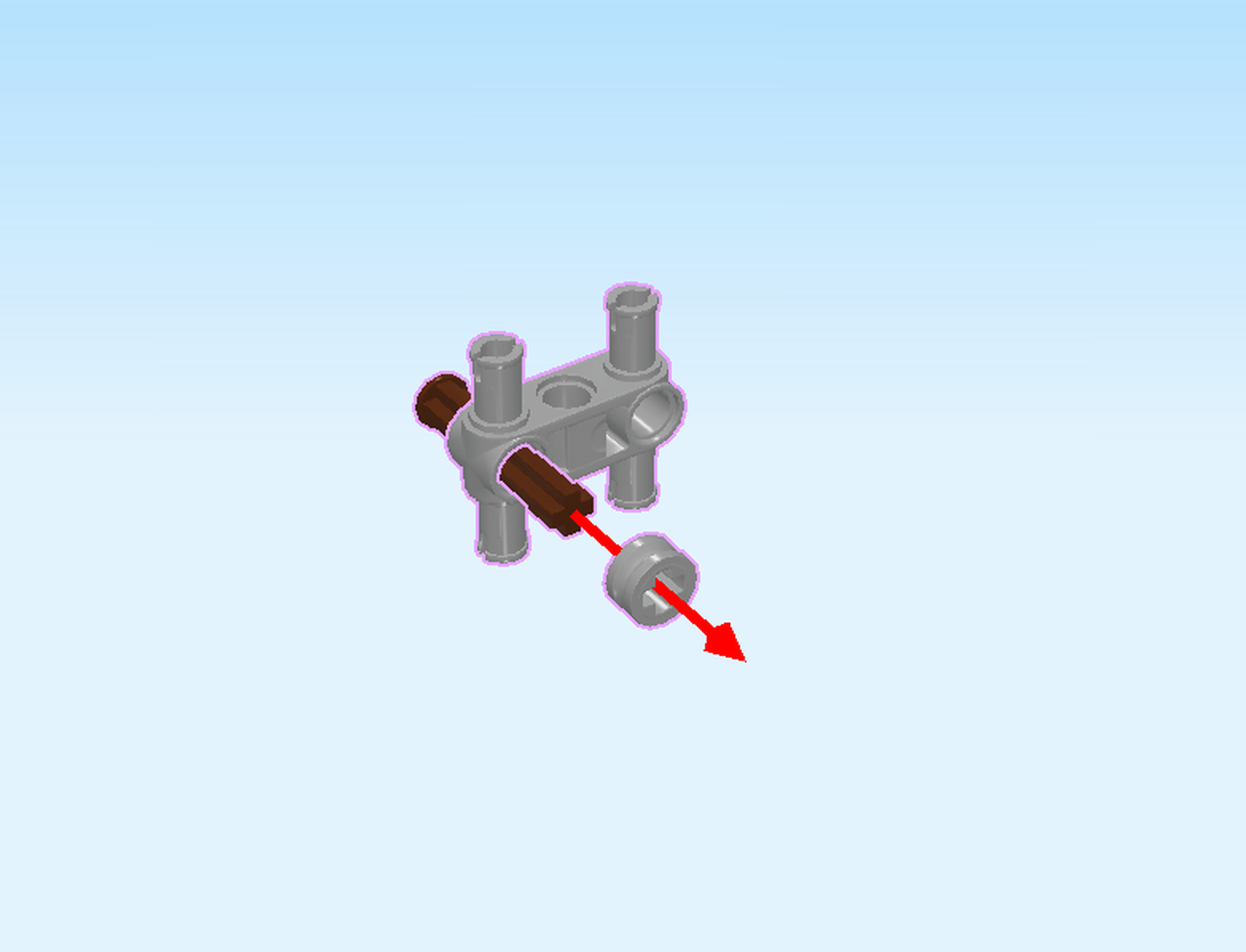

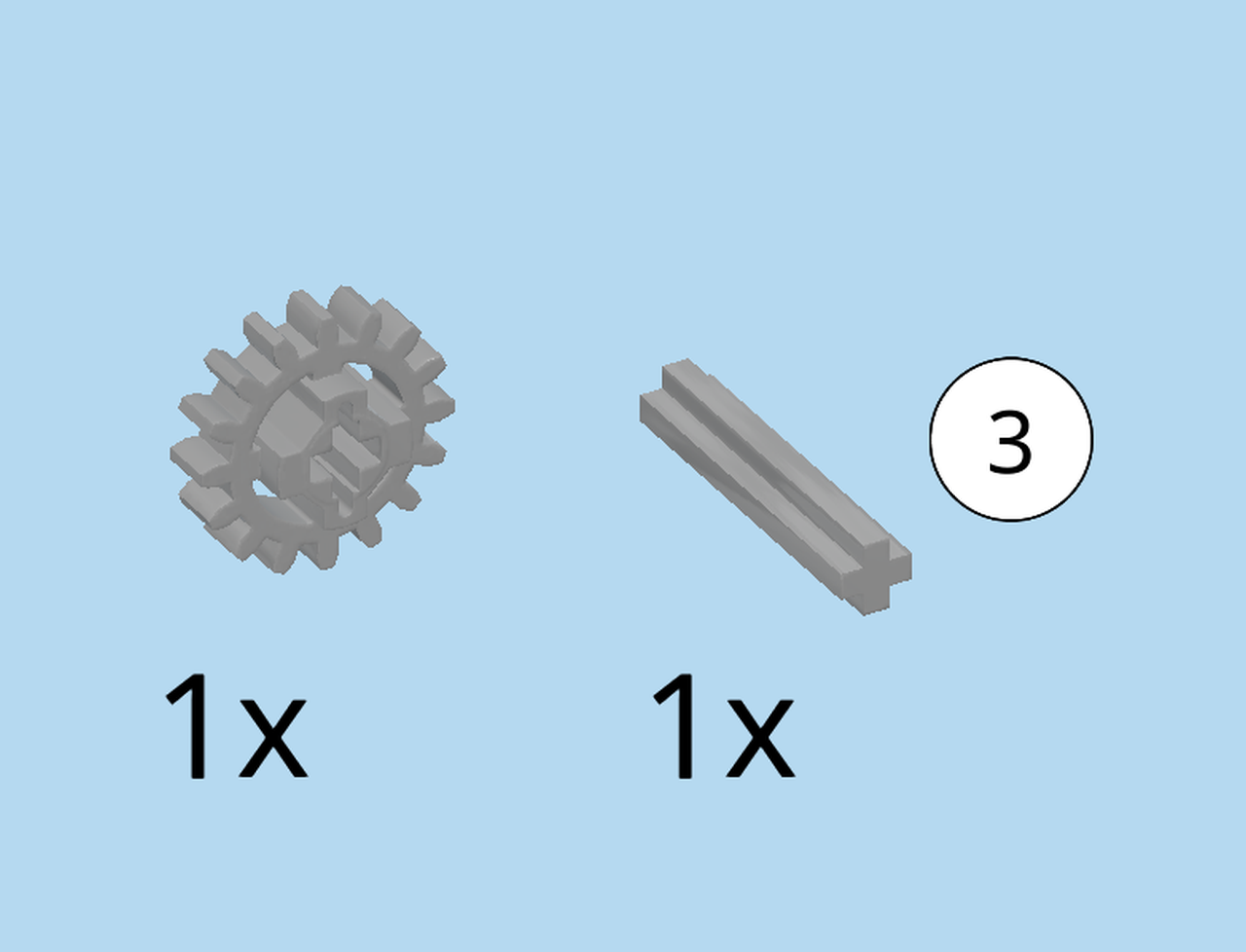

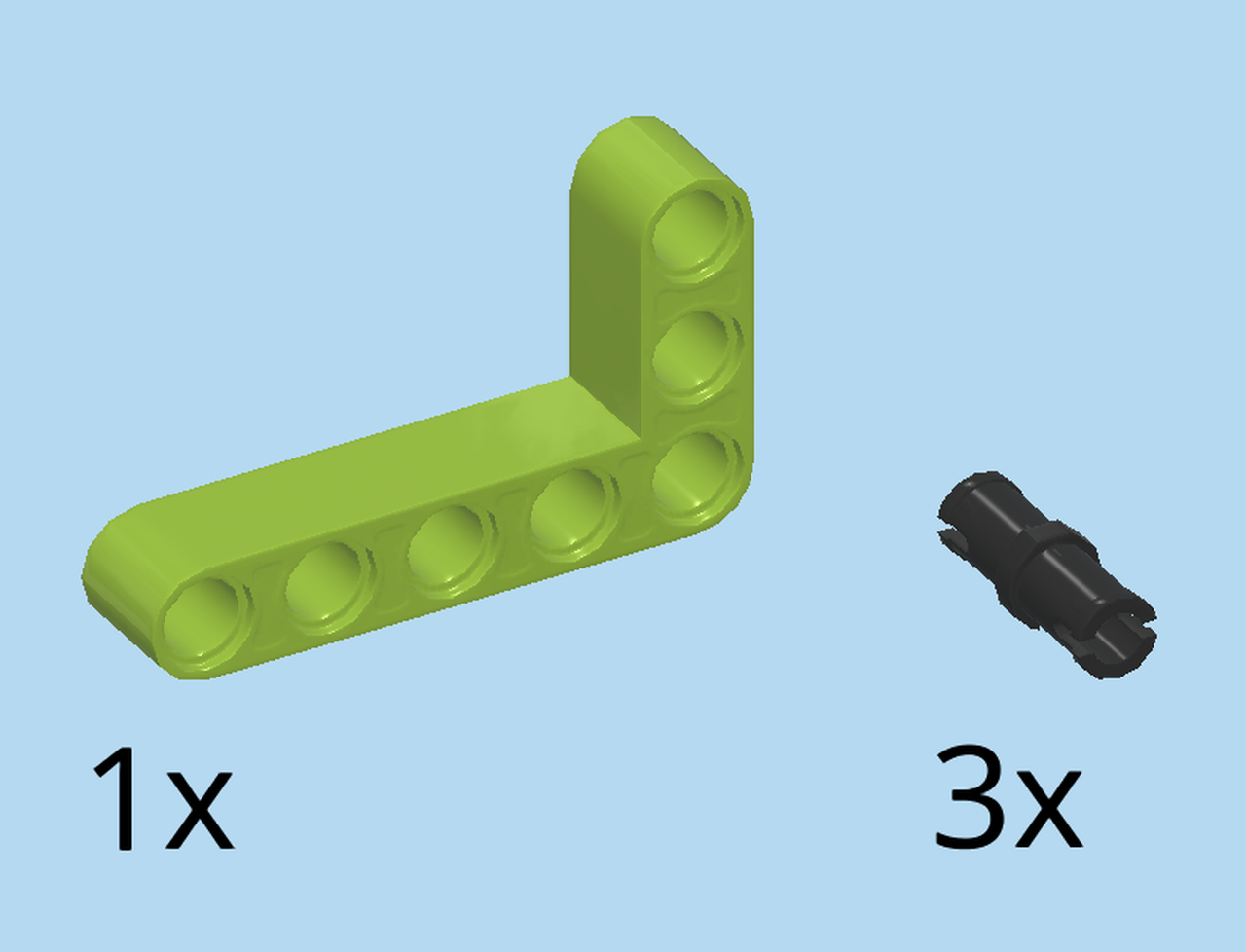

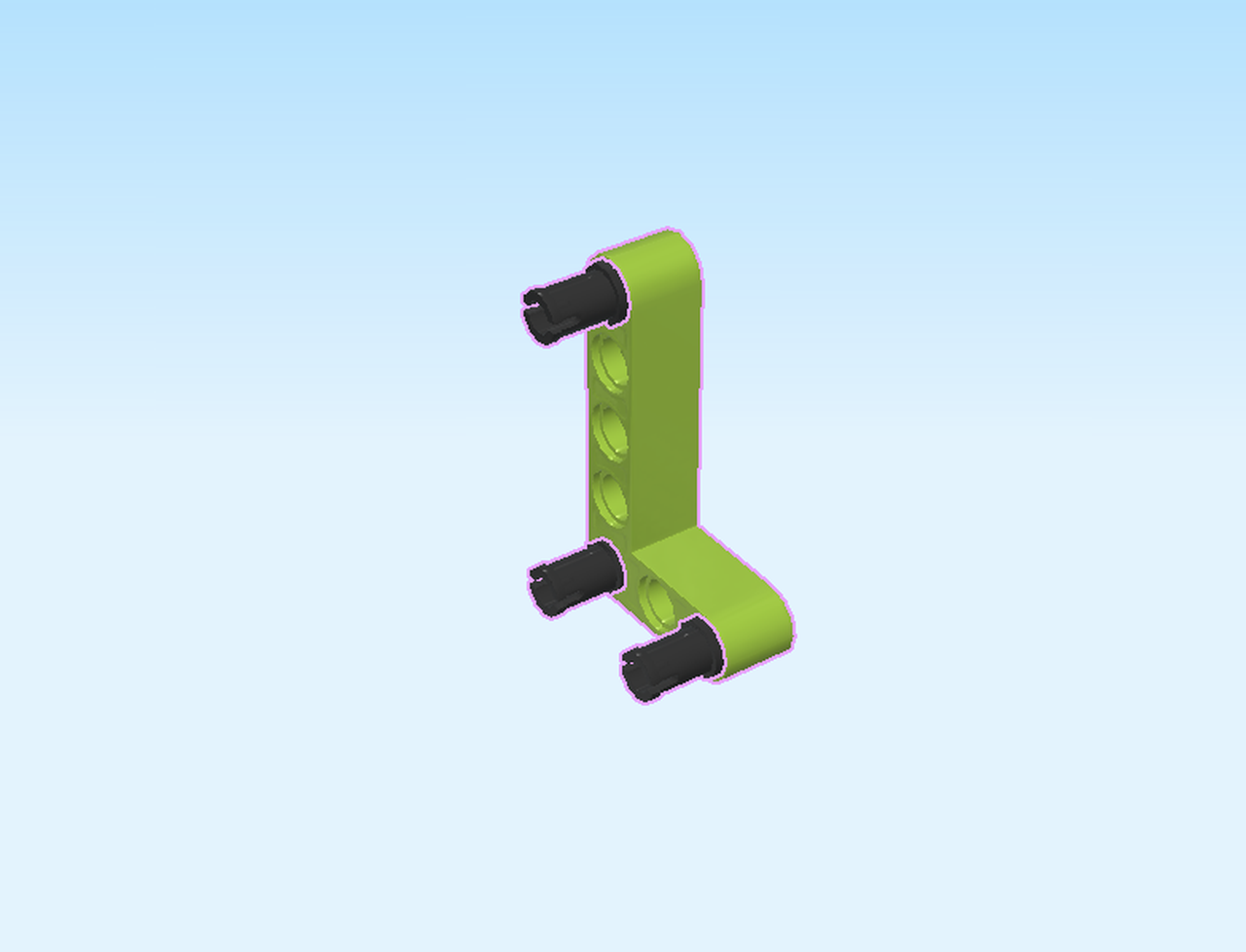

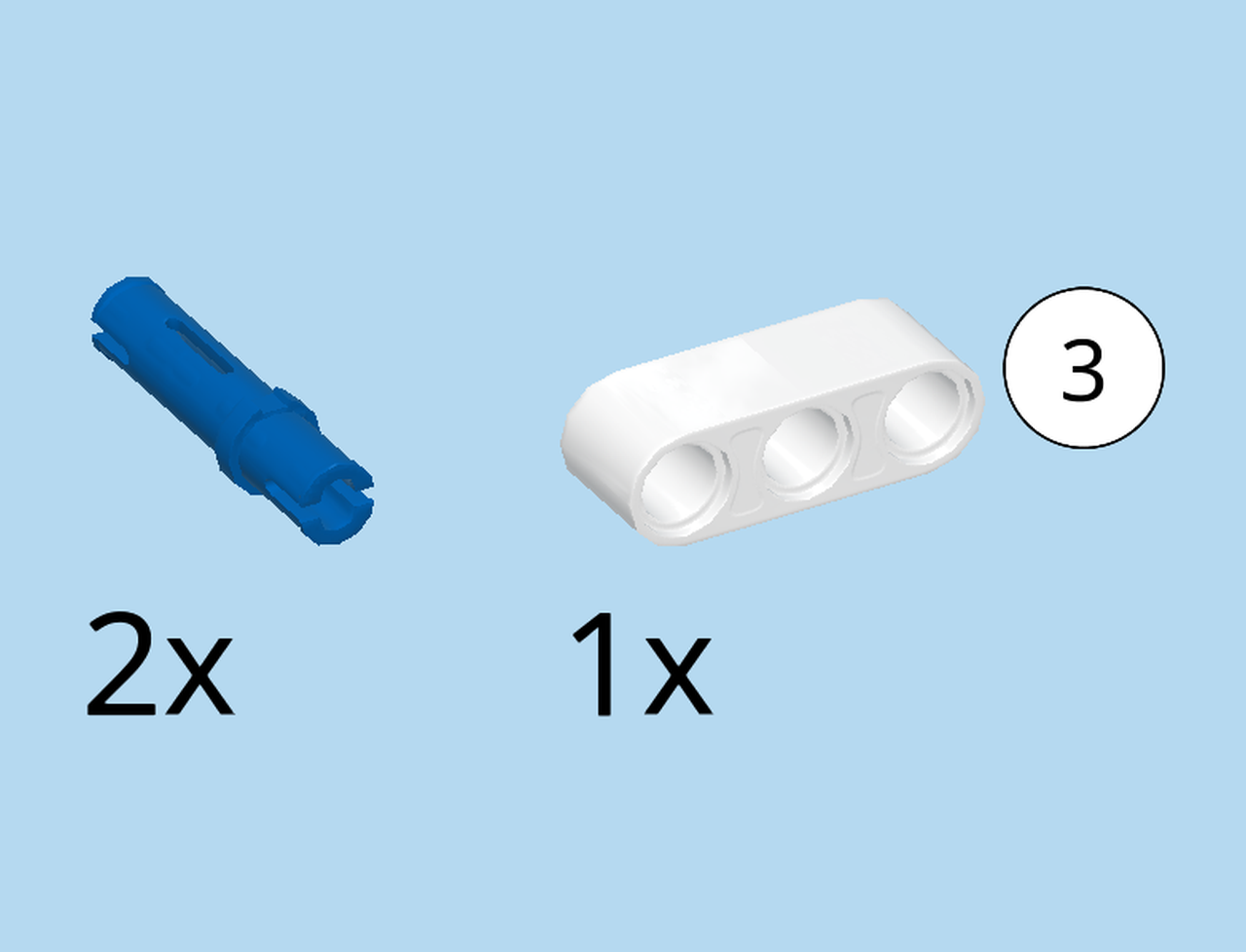

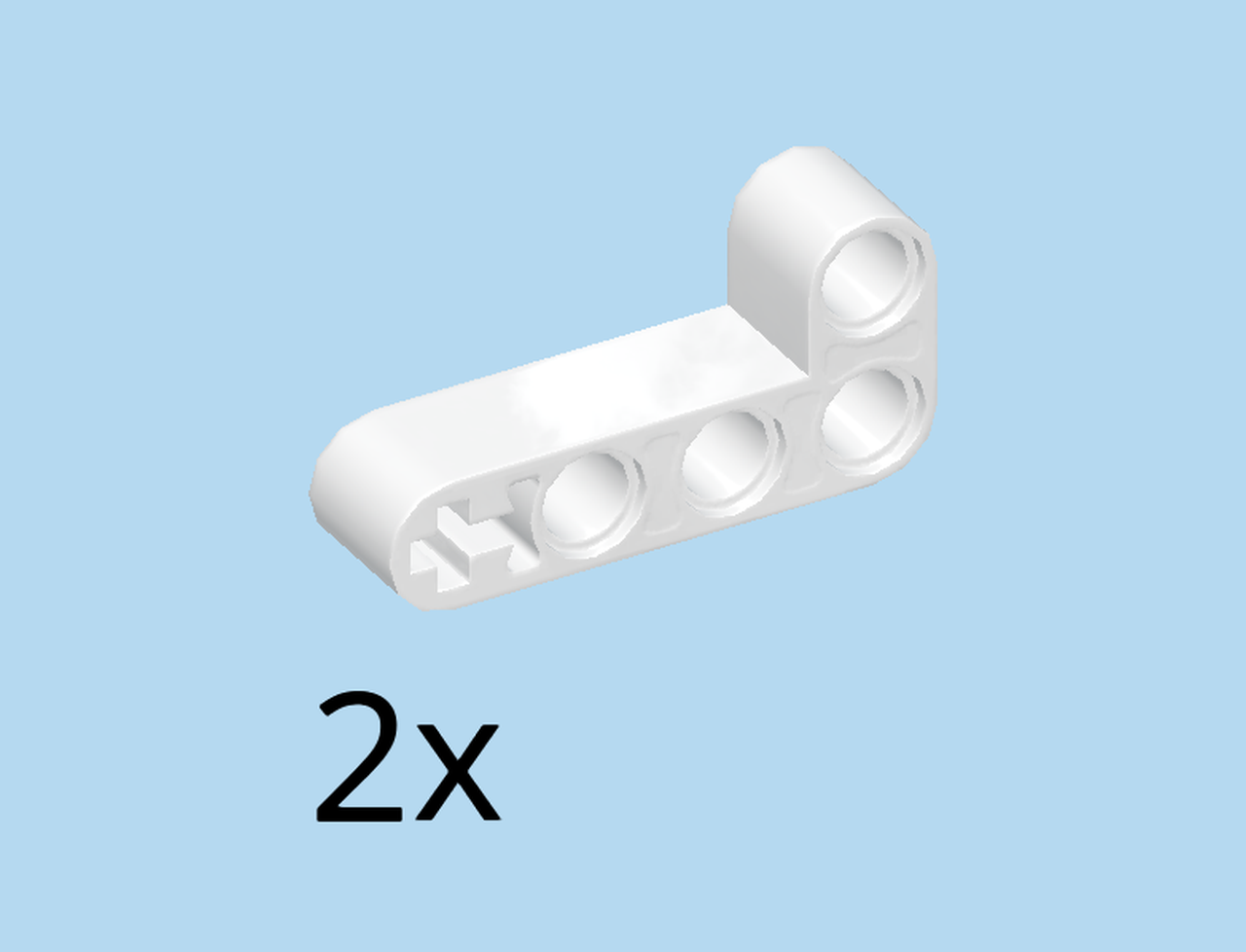

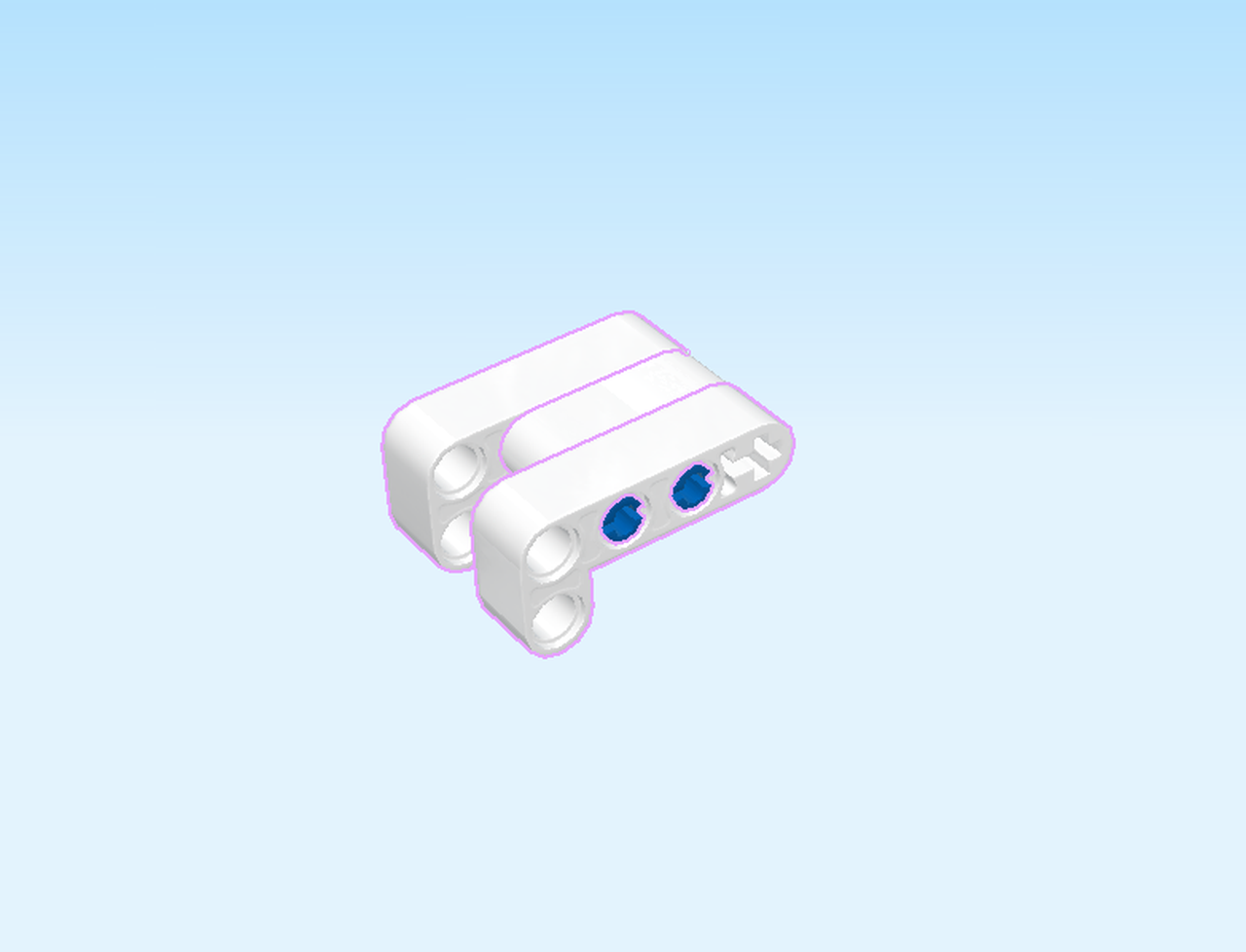

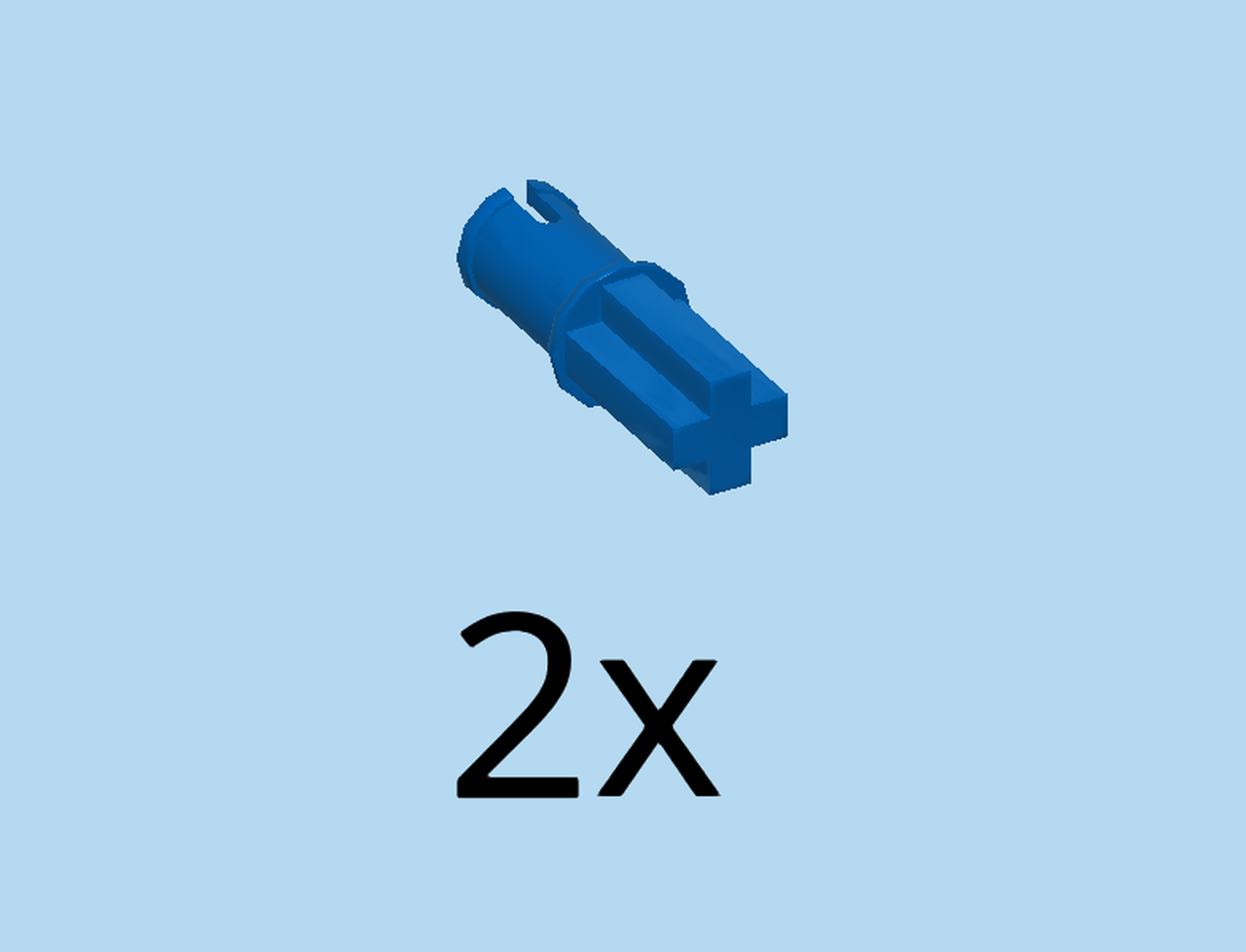

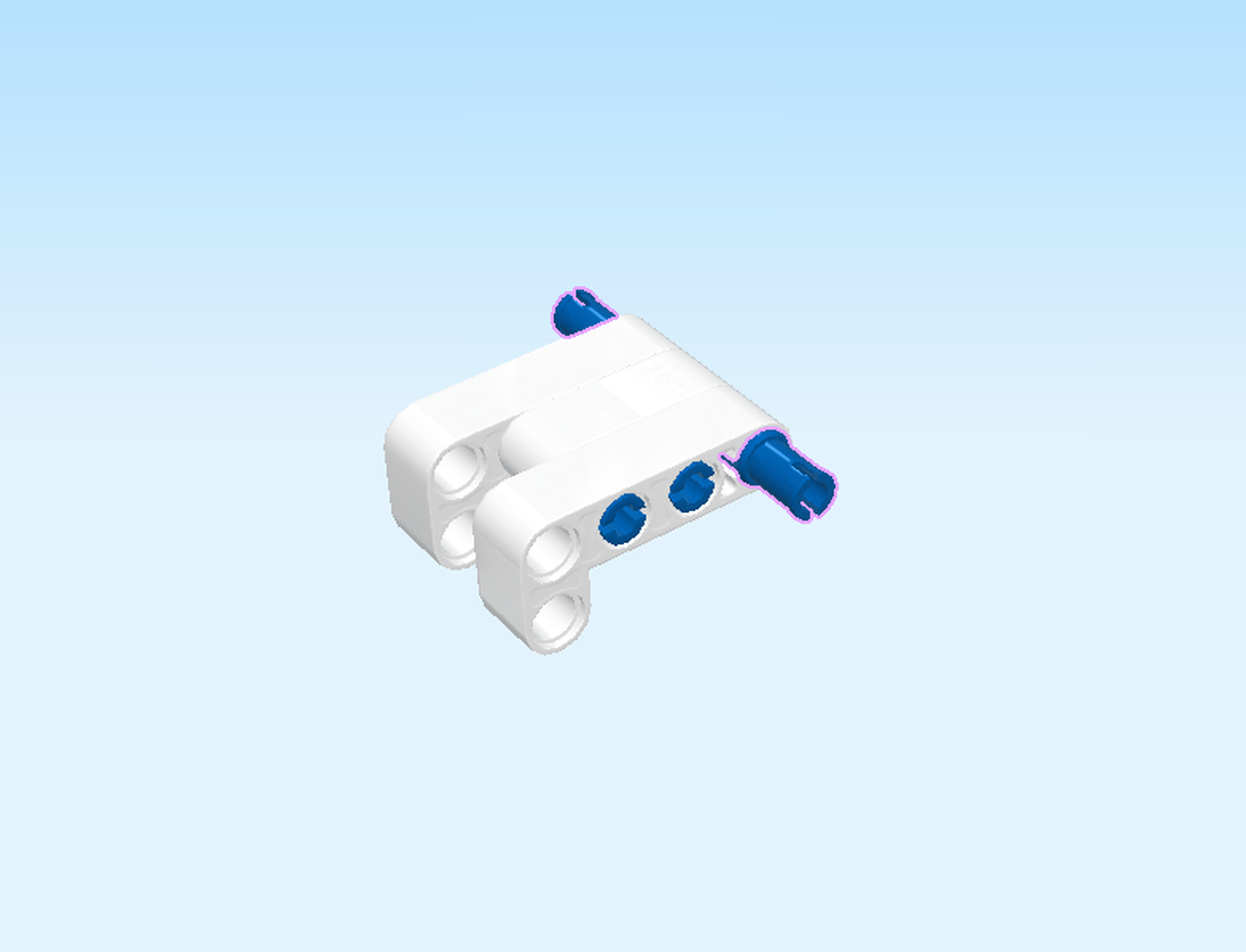

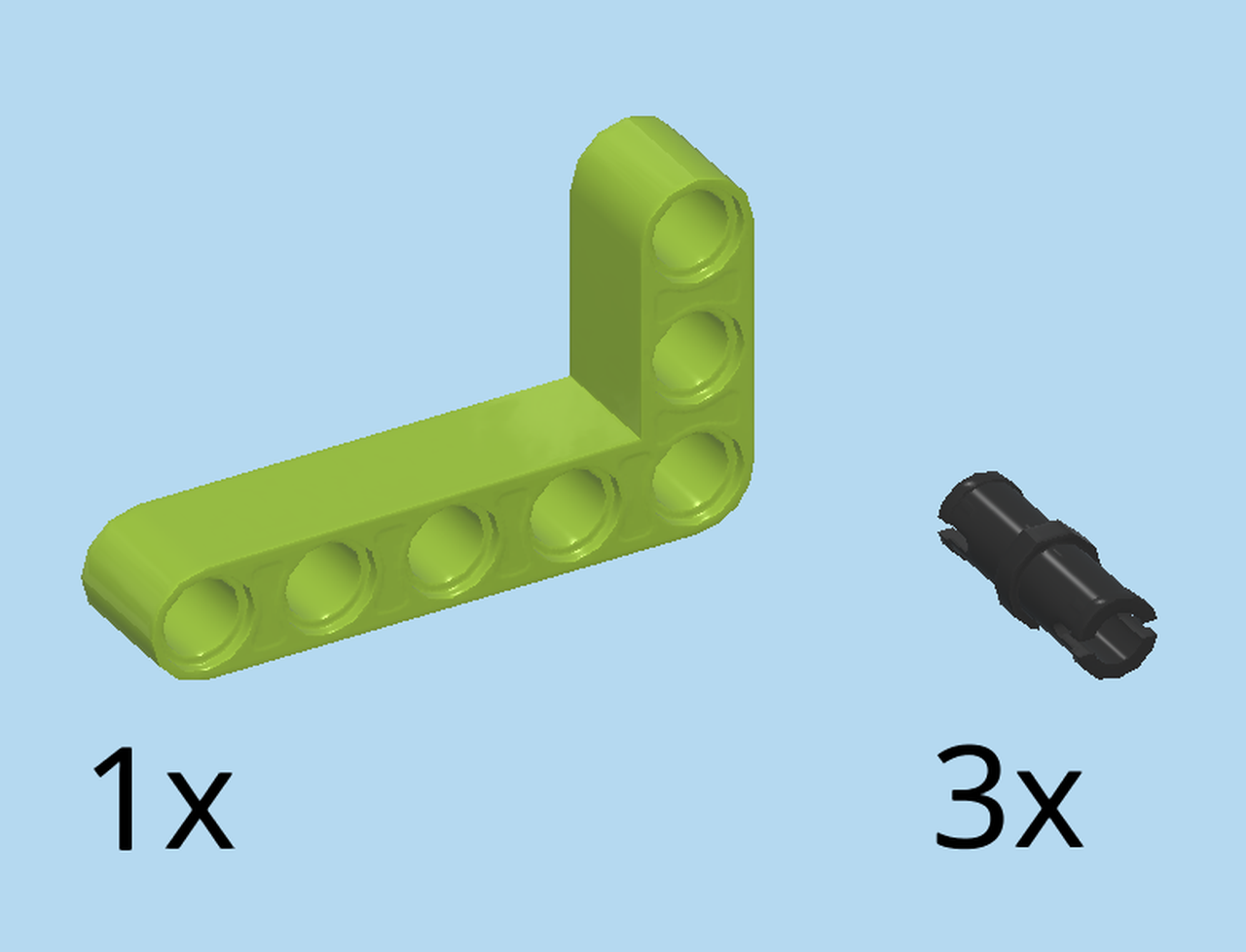

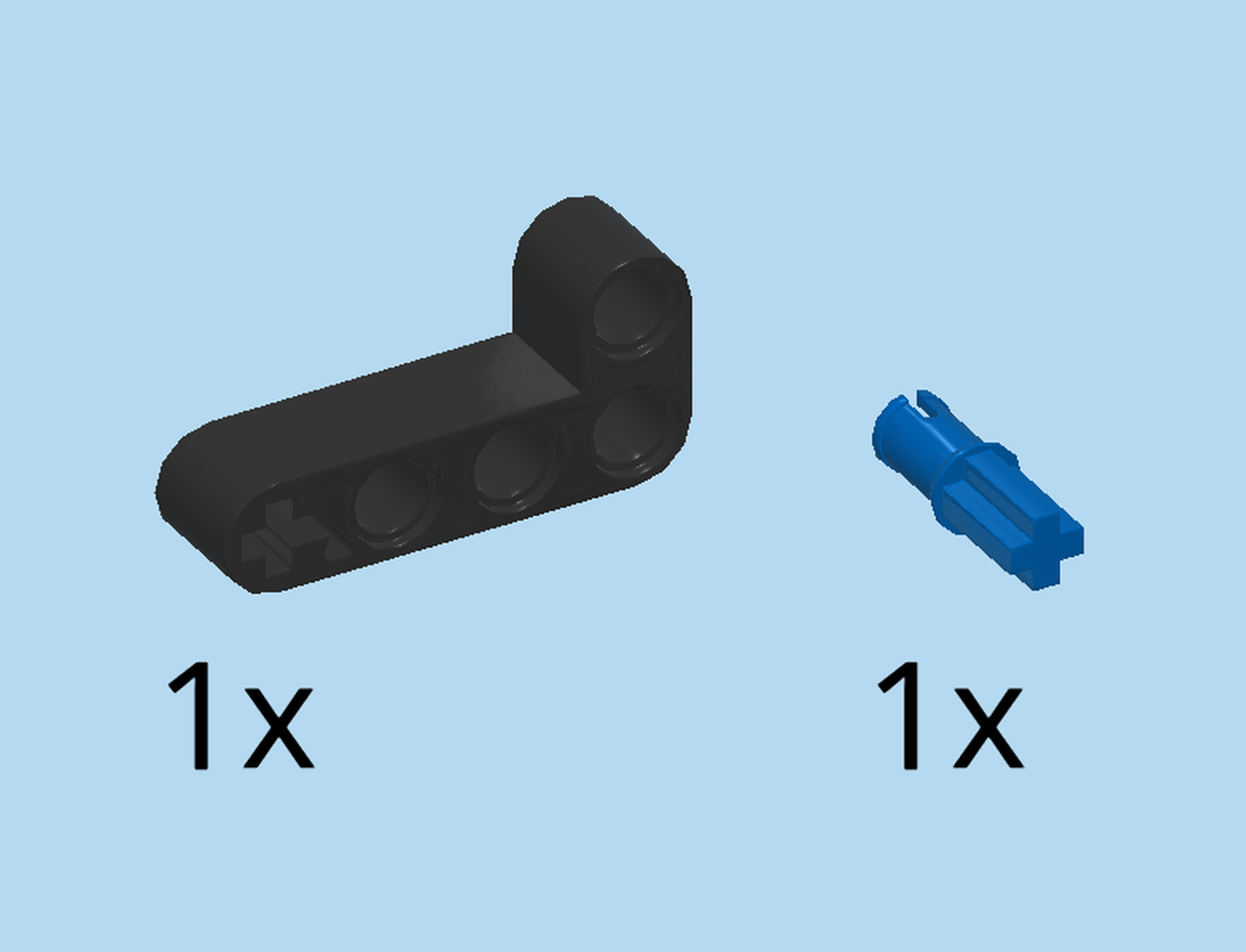

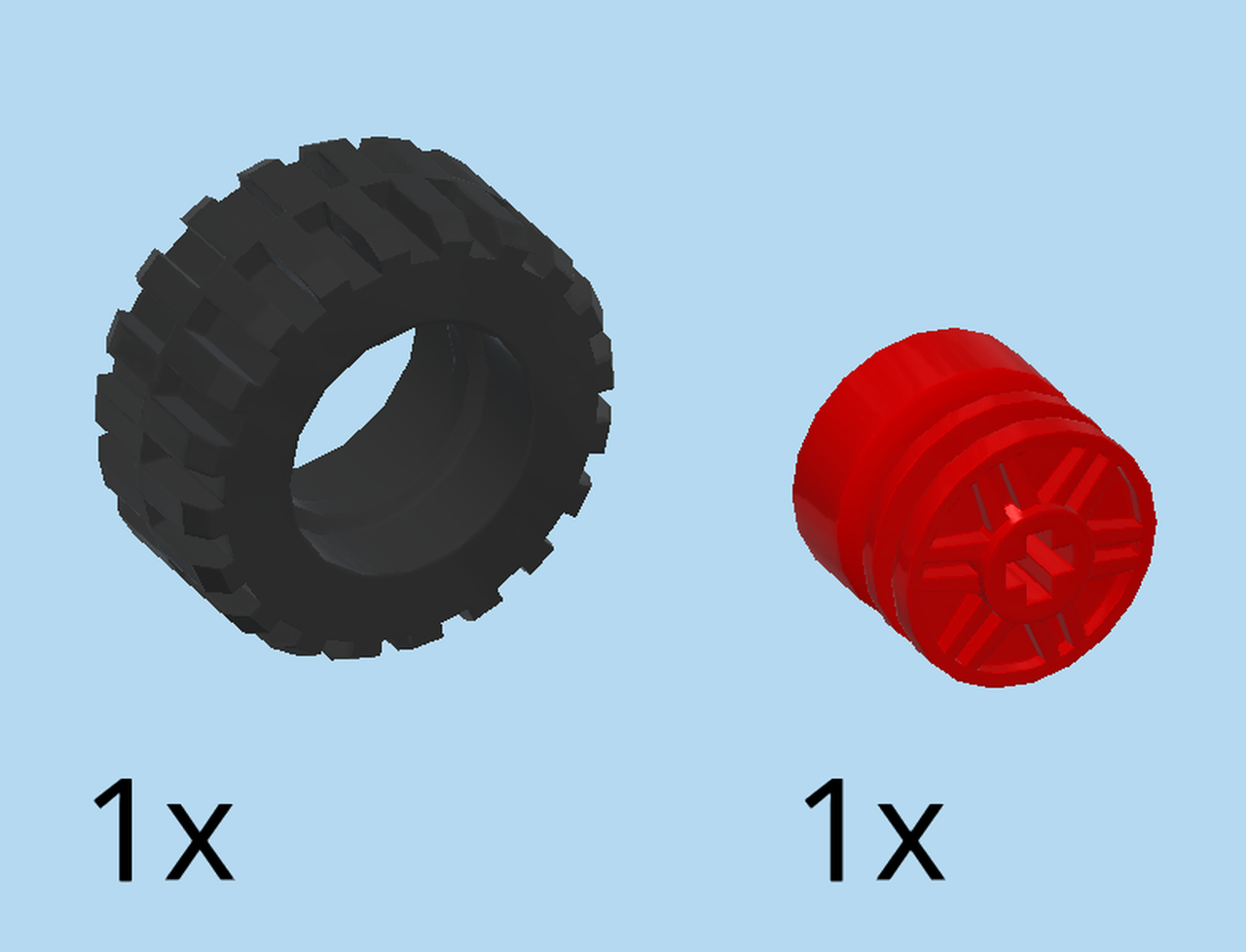

If you haven't built anything with this set yet, open the box. It contains a booklet with visual building instructions, a large and a small plastic bag as well as a sticker sheet with four stickers. Open both plastic bags carefully.

If you have built the tractor before, take everything apart.